Categories

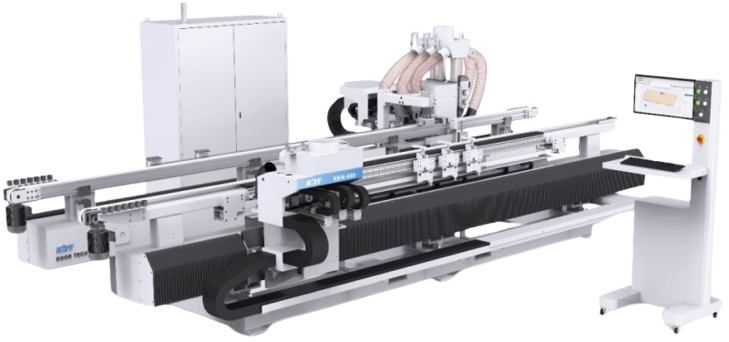

The 612 KHSA Throughfeed Drilling/Routing CNC machine with robotic manipulation and conveyors is an advanced production system designed for high precision and automation in industrial processes. This machine enables continuous material processing with an integrated robotic arm that ensures precise workpiece manipulation. Conveyor belts allow efficient and fast material flow through the different processing stages, increasing productivity and reducing cycle times. The system is ideal for mass production, where speed, accuracy and reliability are key.

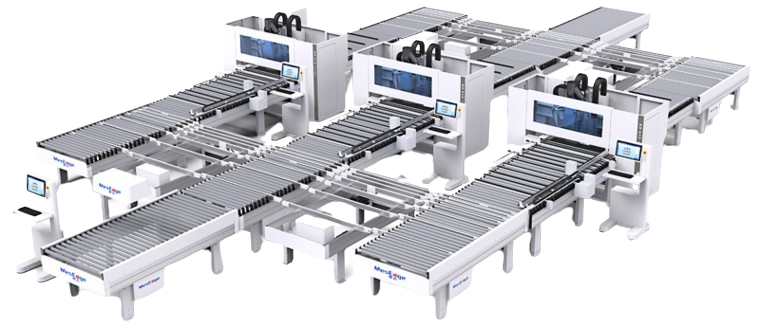

KDT 612 Drilling/Routing CNC machine line with automatic scanning and roller track is a highly efficient solution for the automated processing of materials in an industrial environment. This advanced line enables continuous and precise machining thanks to an integrated automatic scanning system that ensures optimal positioning and machining of workpieces. The roller track enables the smooth transport of materials through the various stages of processing, which increases productivity and reduces downtime. It is ideal for mass production where speed, accuracy and process reliability are key.

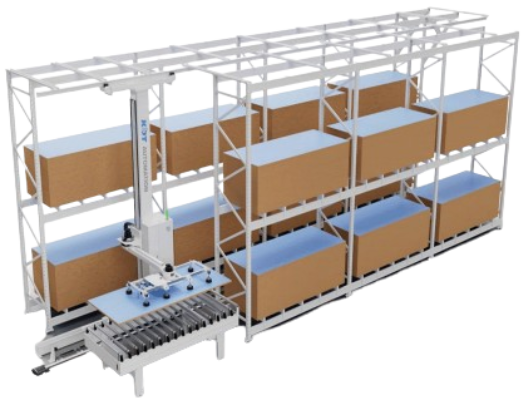

The KDT nesting cutter with a capacity of 30 panels per hour is a high-performance machine designed for accurate and efficient panel cutting. This machine is designed to optimize material utilization by using advanced nesting technology that allows maximum panel utilization. With a capacity of up to 30 plates per hour, it is ideal for intensive production in industrial environments where speed, accuracy and waste reduction are key. The system ensures a high degree of automation and flexibility, which allows adaptation to different processing requirements and specifications.