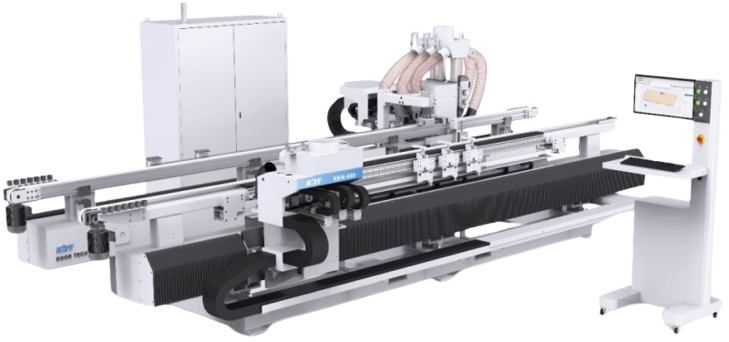

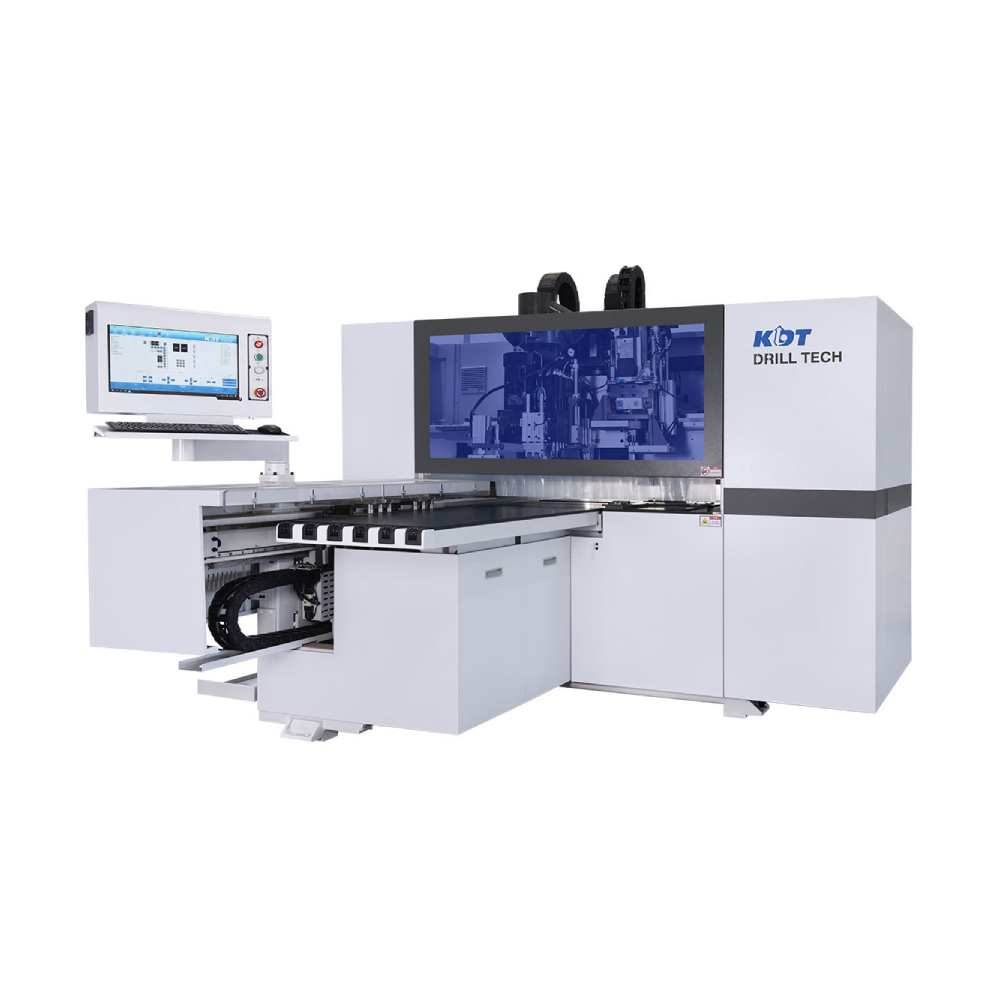

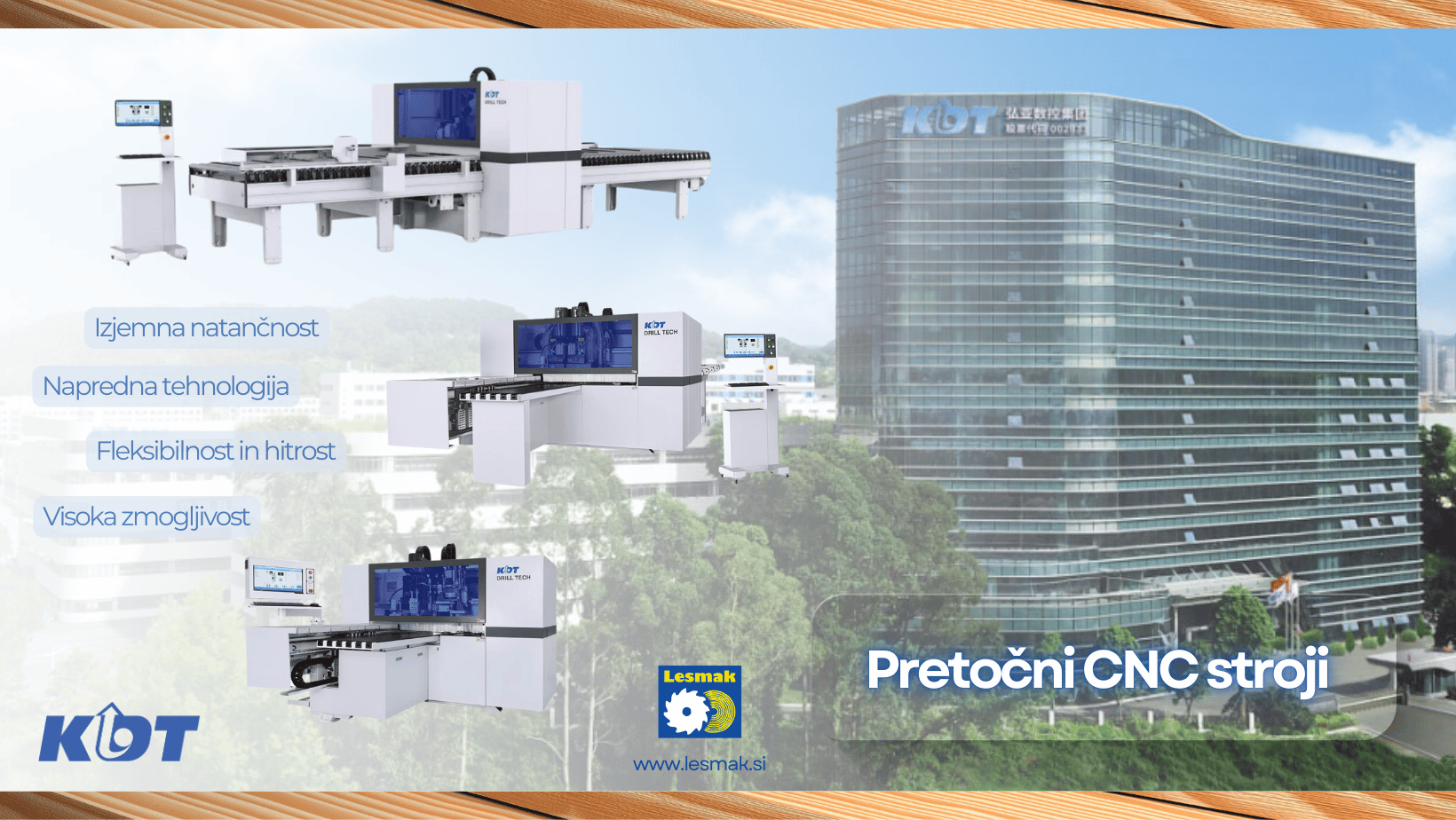

Drilling/Routing CNC machine KDT KD-610 HZ

Machine operation is easy on a personal industrial Windows PC and the user-friendly KDT DrillTop software. A barcode reader is included for working with barcodes. The KDT KN-610 HZ machine has ONLINE service enabled with TeamViewer. Programs can be created both on the machine and in the office. It is possible to connect the machine to programs such as MegaTISCHLER, Corpus 3D, LestrojBox, Alphacam and Solidworks. The program is easy to use, graphically supported and parametric.

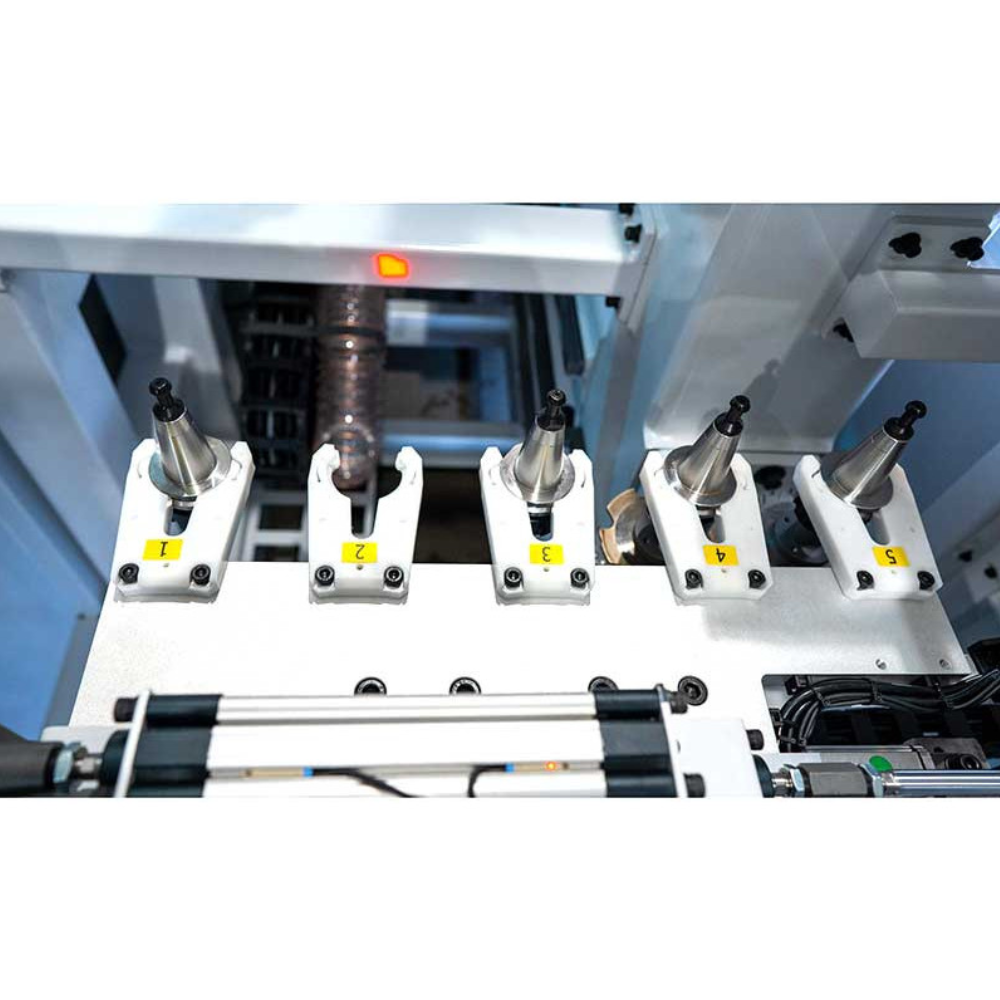

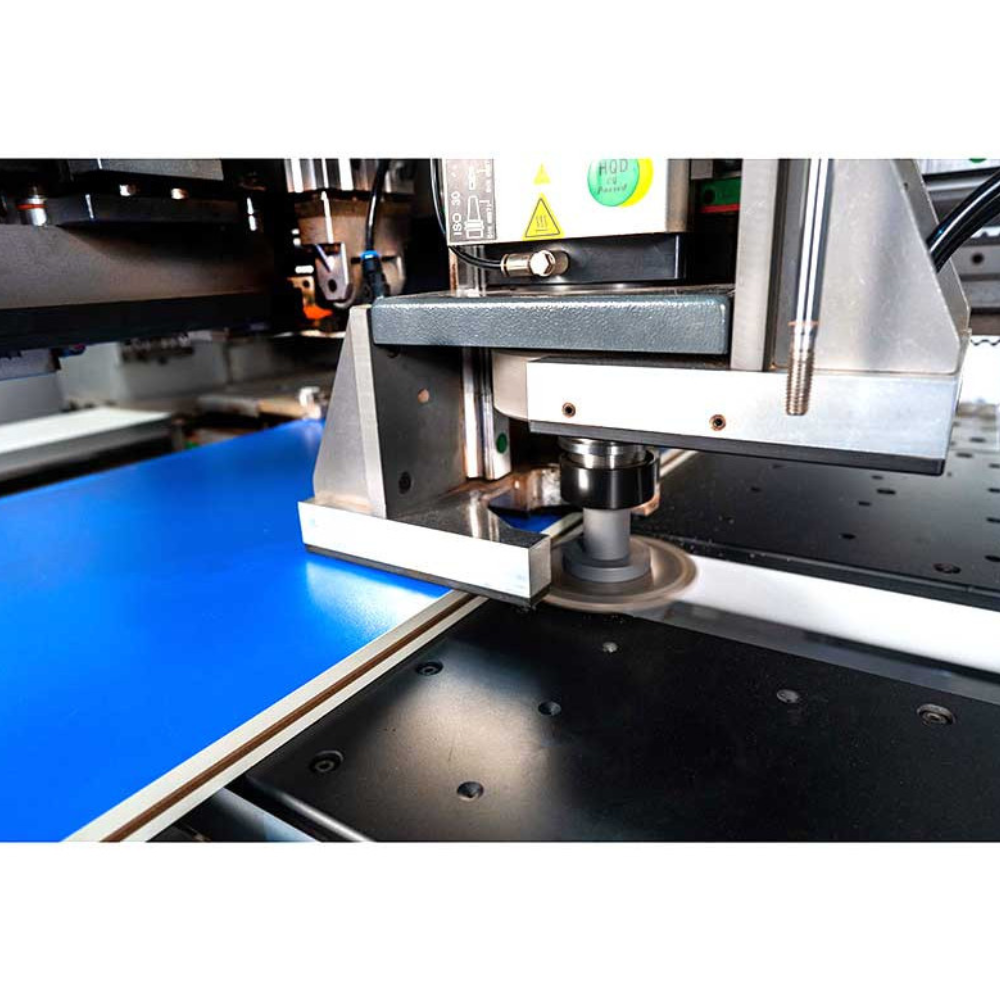

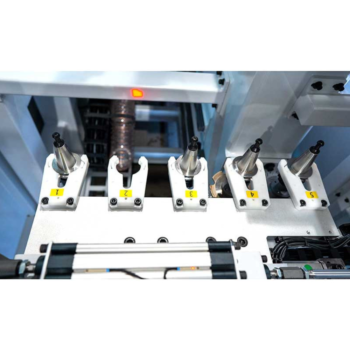

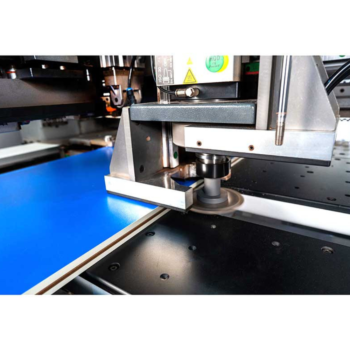

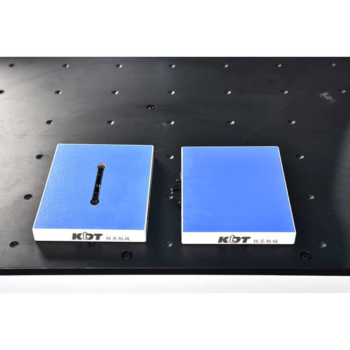

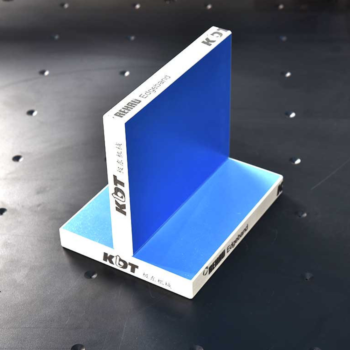

KD-610 HZ is equipped with a 5.5 kW milling unit for grooves and cutouts with automatic tool change and a 5-position tool magazine and an integrated 120 mm diameter groove saw intended for making a groove for backs.

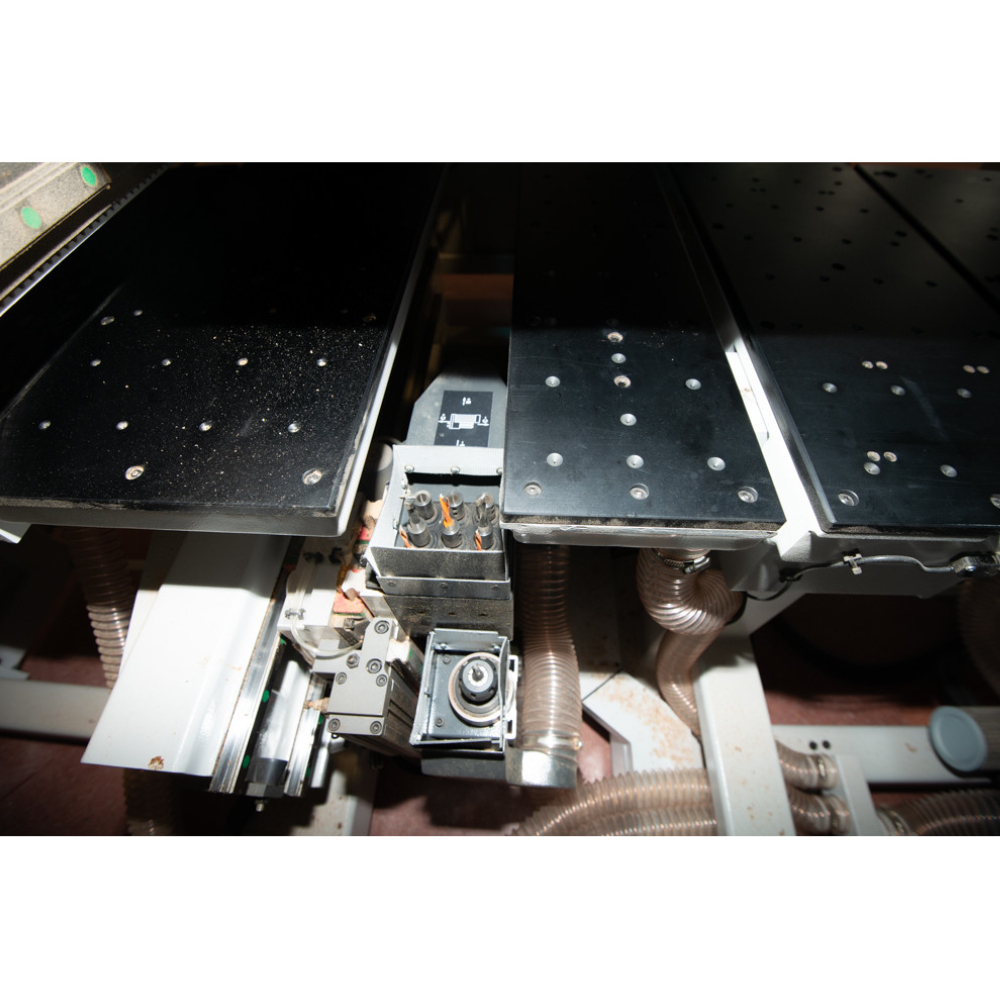

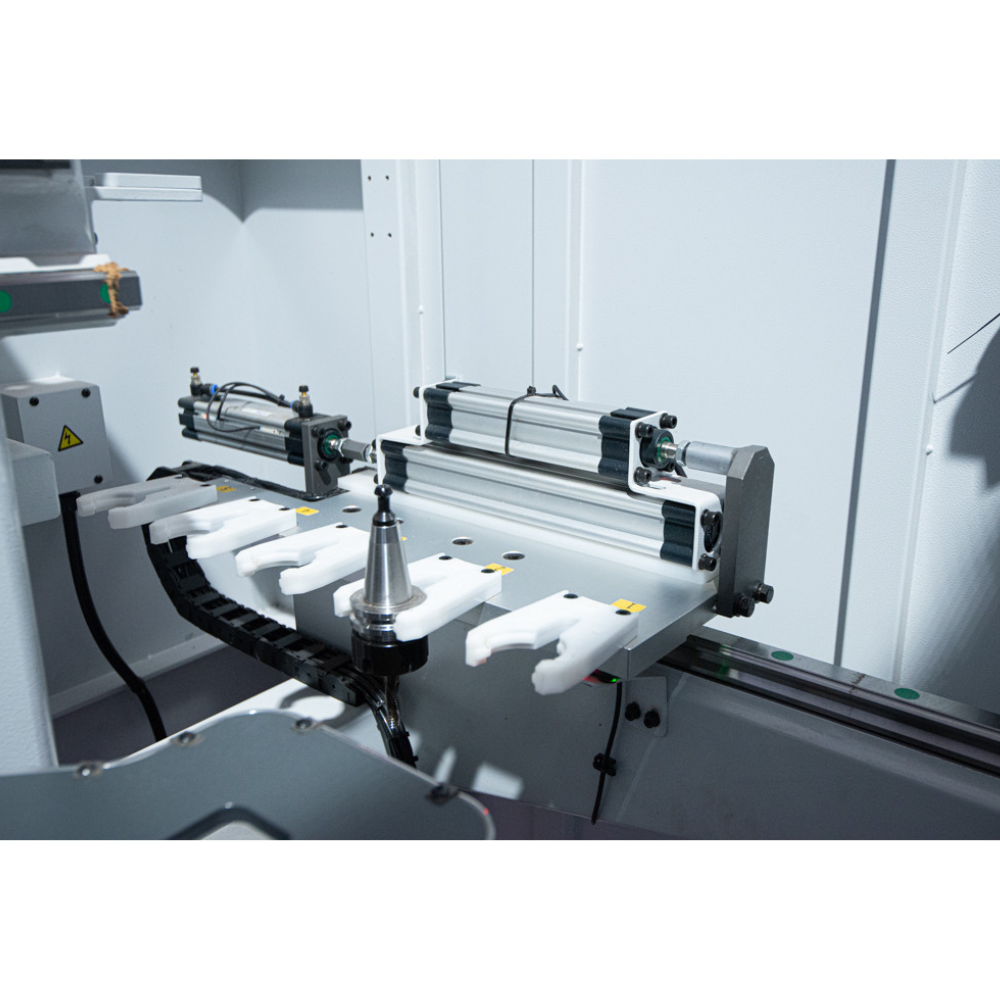

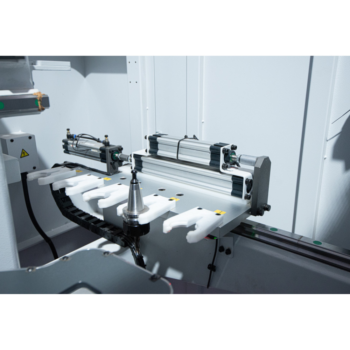

The CNC machine is equipped with a pair of independent clamps and automatically adjusts the clamps according to the position of the holes. The length of the pliers guides is 5500 mm for processing long pieces without gripping the pliers.Entry air worktable is for easier movement of workpieces, especially workpieces with a sensitive surface.

Double pliers are intended for faster work and more precise gripping. The conveyor belt is intended for moving waste material from the machine.

Flow CNC KDT KD-610 HZ is easy to use, as it does not require mechanical settings, and with the use of barcodes, it does not require an experienced user to work directly on the machine.

Technical characteristics and equipment of the machine

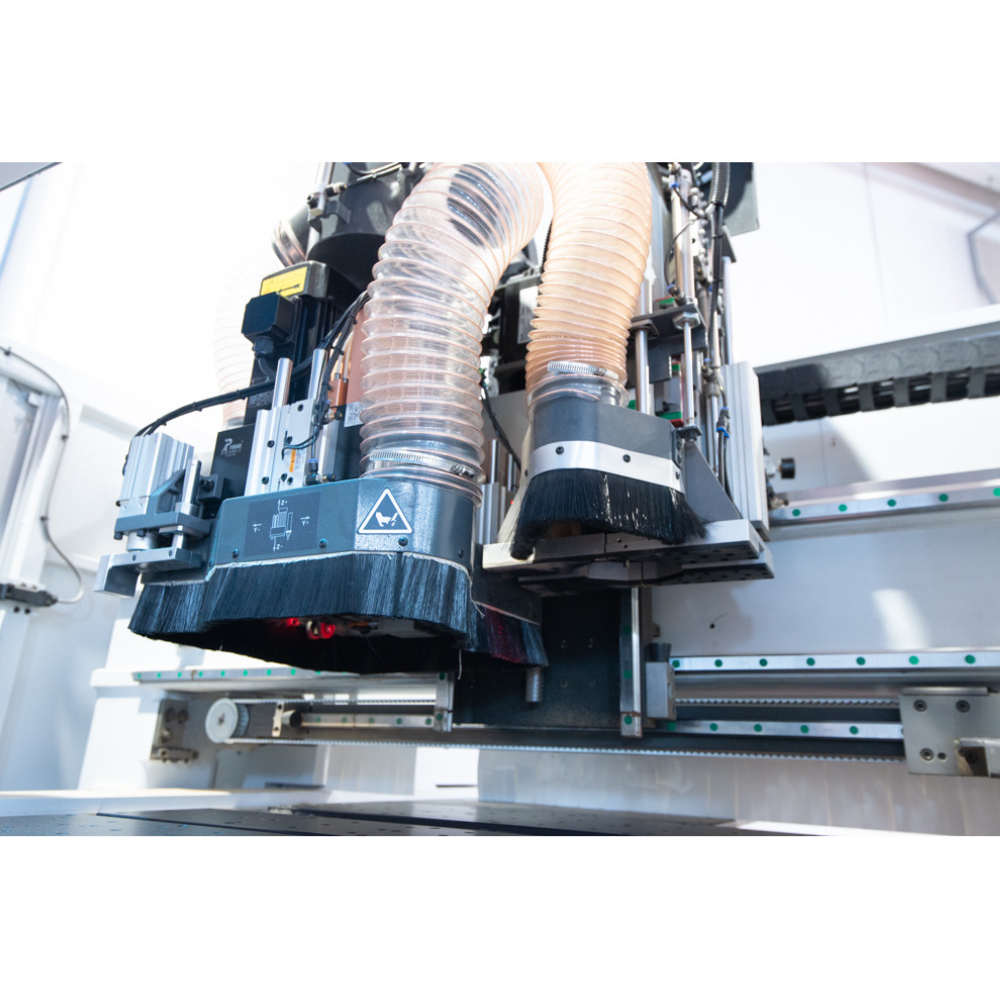

- 2 independent drilling units + milling unit 5.5 kW with automatic tool change,

- drilling units (above) with 12 vertical + 8 horizontal drills,

- one drilling unit (below) with 9 vertical drills,

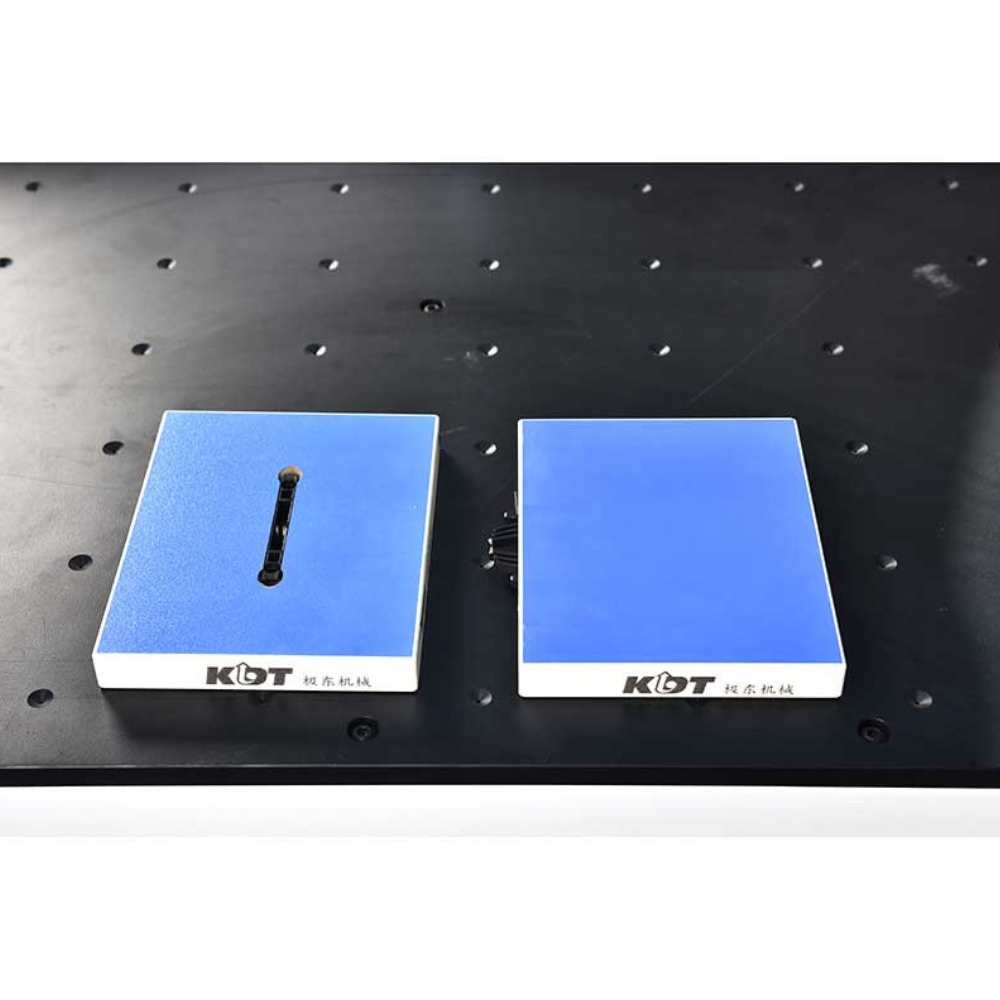

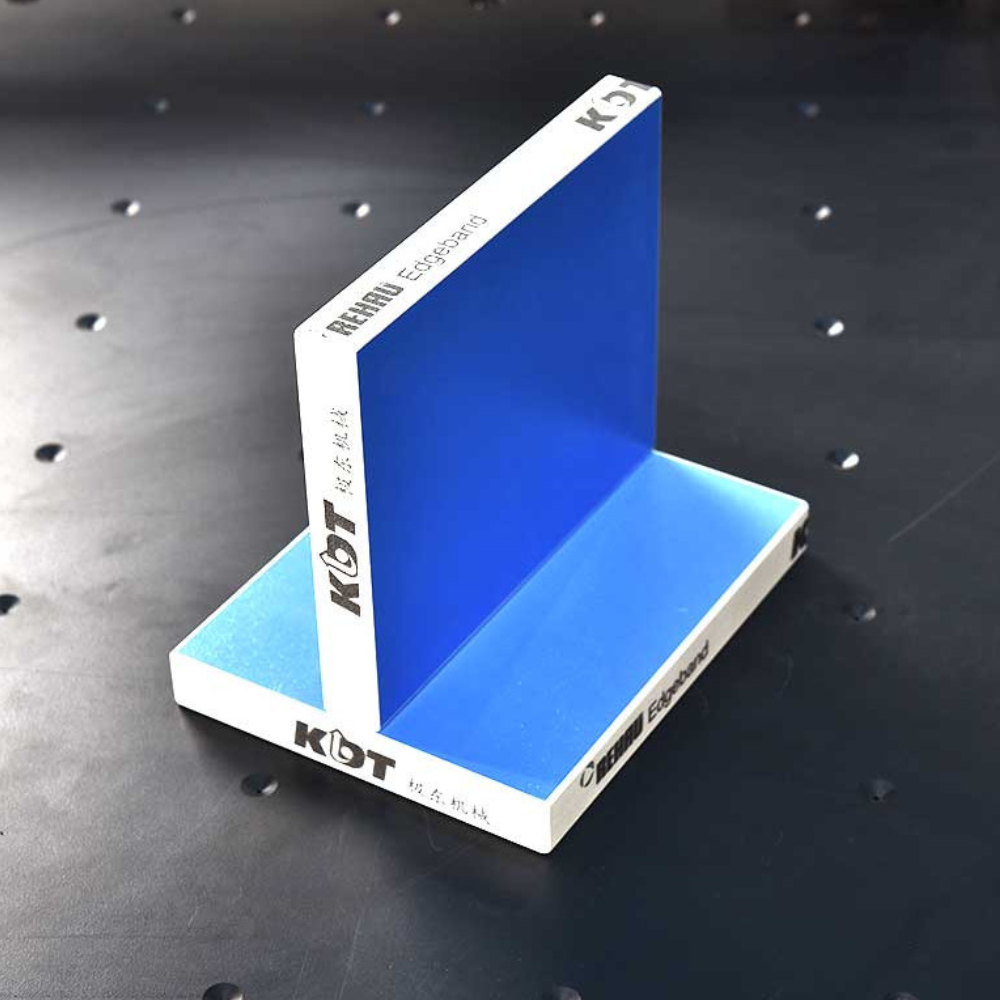

- processing from all six sides of the workpiece,

- integrated saw diameter 120 mm and thickness 4 mm,

- industrial personal computer with Windows environment and KDT software, controller,

- double independent pincers,

- barcode reader,

- input air table + output air work table.

- safety guardrails and CE certificate,

- length of the workpiece: 70 - 2850 mm,

- width of the workpiece: 50 - 1000 mm or min. width 35 mm, if the workpiece is shorter than 1000 mm,

- workpiece thickness: 9 - 60 mm,

- moving speed of the tongs: 140 m/min,

- total dimensions: 7300 × 2660 × 2190 mm,

- total connected power: 21.9 kW,

- weight: 2900 kg.