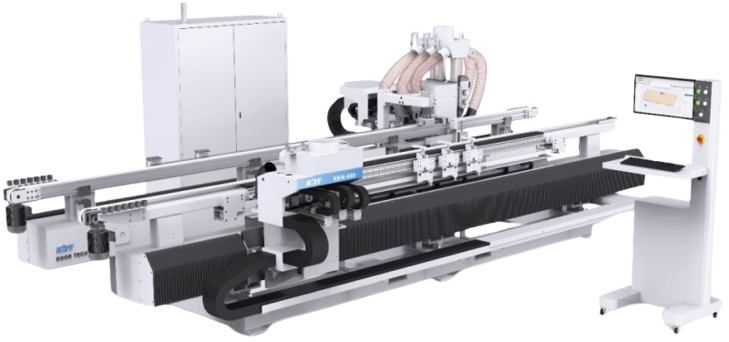

TPA rocker and TPA CAD/CAM program equipment from a recognized Italian manufacturer.

The program is the result of many years of development and experience and allows the user to use it easily, while at the same time it is powerful enough even for more demanding carpenters.

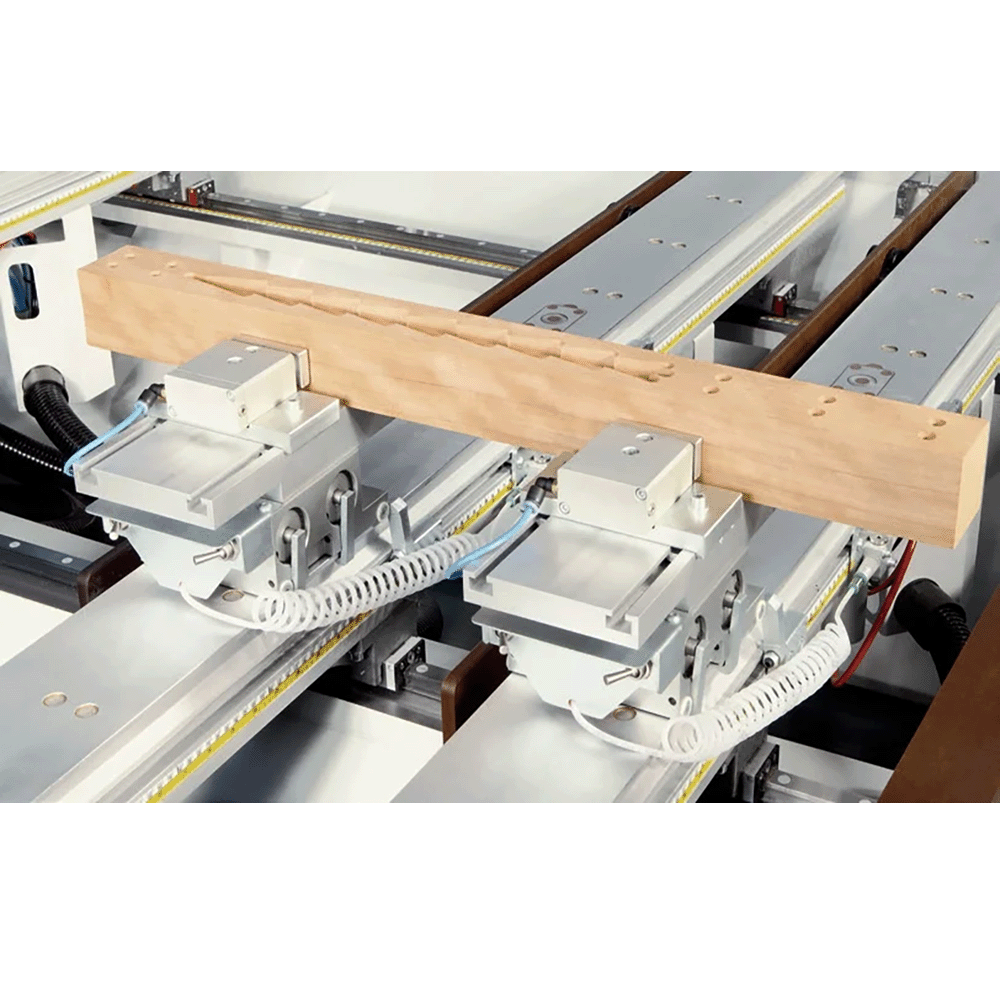

The machine has a working field of 3250×1500 mm and 200 mm along the Z axis. It is equipped with SIX tubeless supports and renowned SCHMALZ vacuum grippers and a powerful BECKER vacuum pump with a flow rate of 250 m3/m.

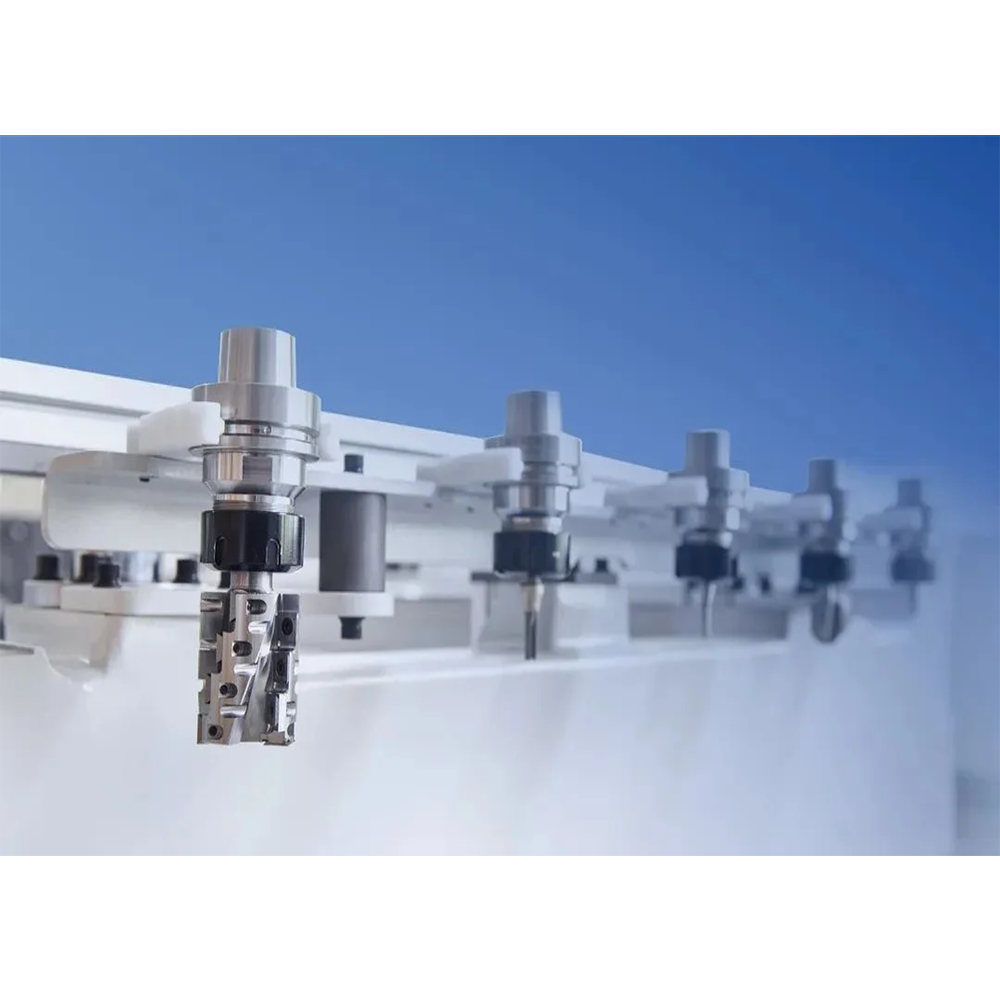

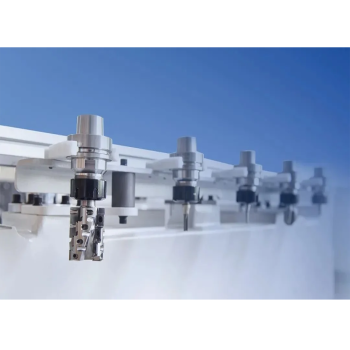

Extraordinary main milling 5 AXIS HSD unit with 13.2 kW motor with HSK F63 coupling and fast turret magazine with 16 positions and linear magazine with 5 positions.

Quick change is ensured by a quick tool magazine of 22 positions + an additional lazy magazine of 5 positions, which is installed on the console of the machine.

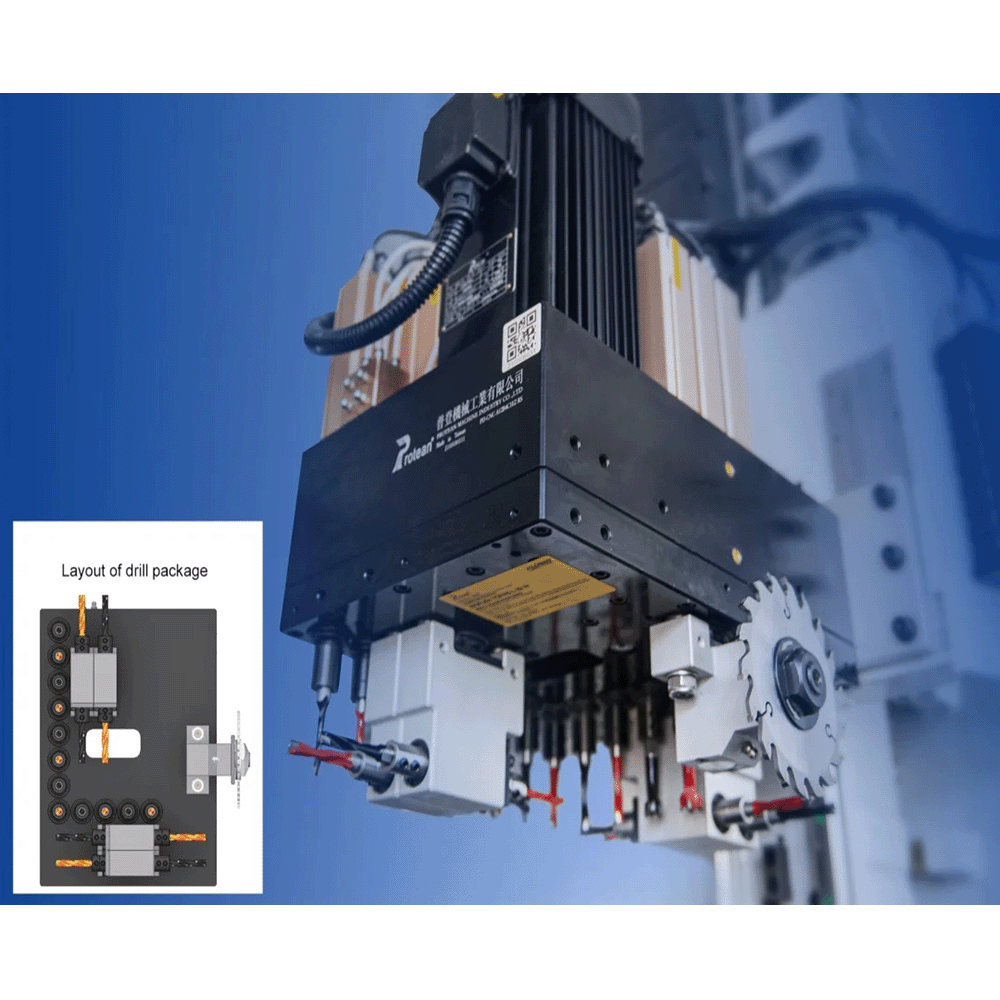

Up to 20 drills and one integrated saw can be installed on the powerful Protean drilling unit. The standard equipment of the KN-5510C machine includes a conveyor belt for waste, which ensures the removal of excess material from the machine.

TECHNICAL DATA:

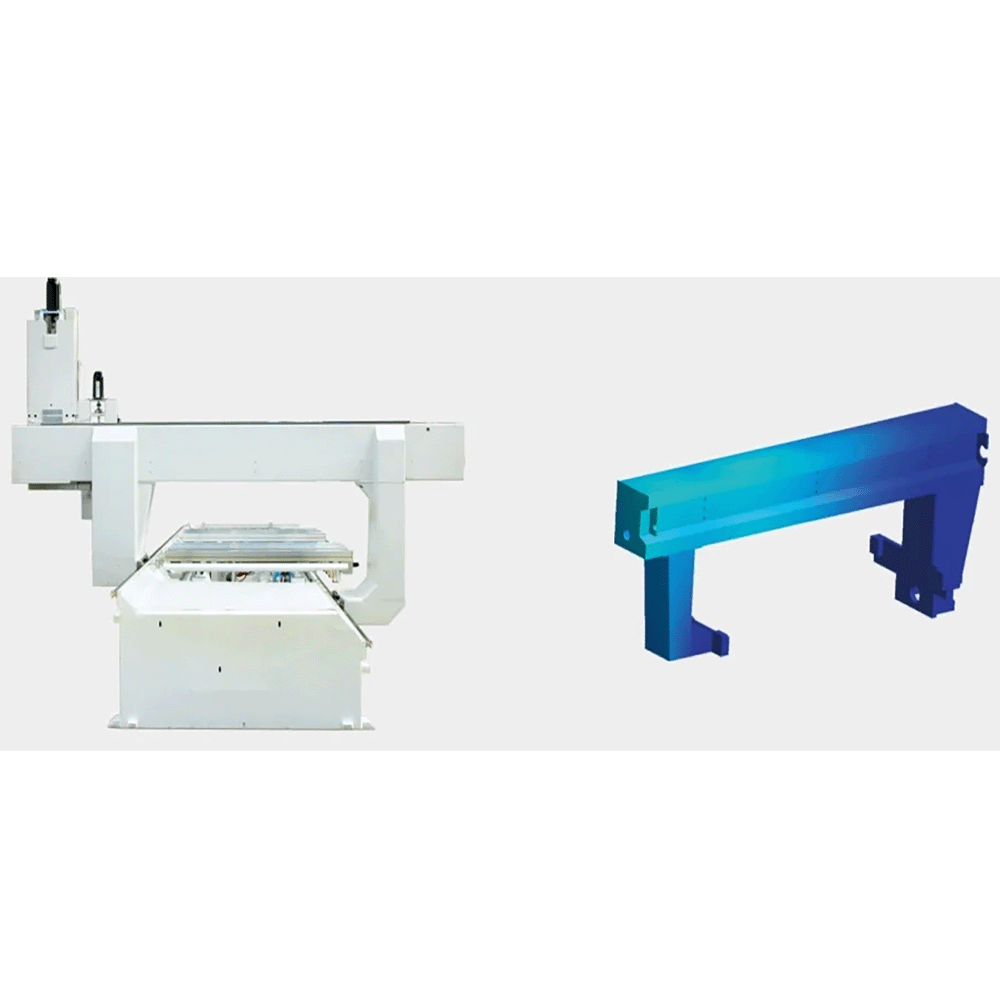

– industrial bridge design – double-sided guides

– processing dimensions (axes X, Y, Z): 3250 × 1500 × 200 mm,

– INDEPENDENT Z axis for drilling unit and milling unit

– HSD milling unit with HSK-F63 attachment and maximum power of 13.2 kW, max. rotation speed 24,000 rpm

– 5 axis unit

– 6 movable tubeless supports and 18 SCHMALZ vacuum grippers,

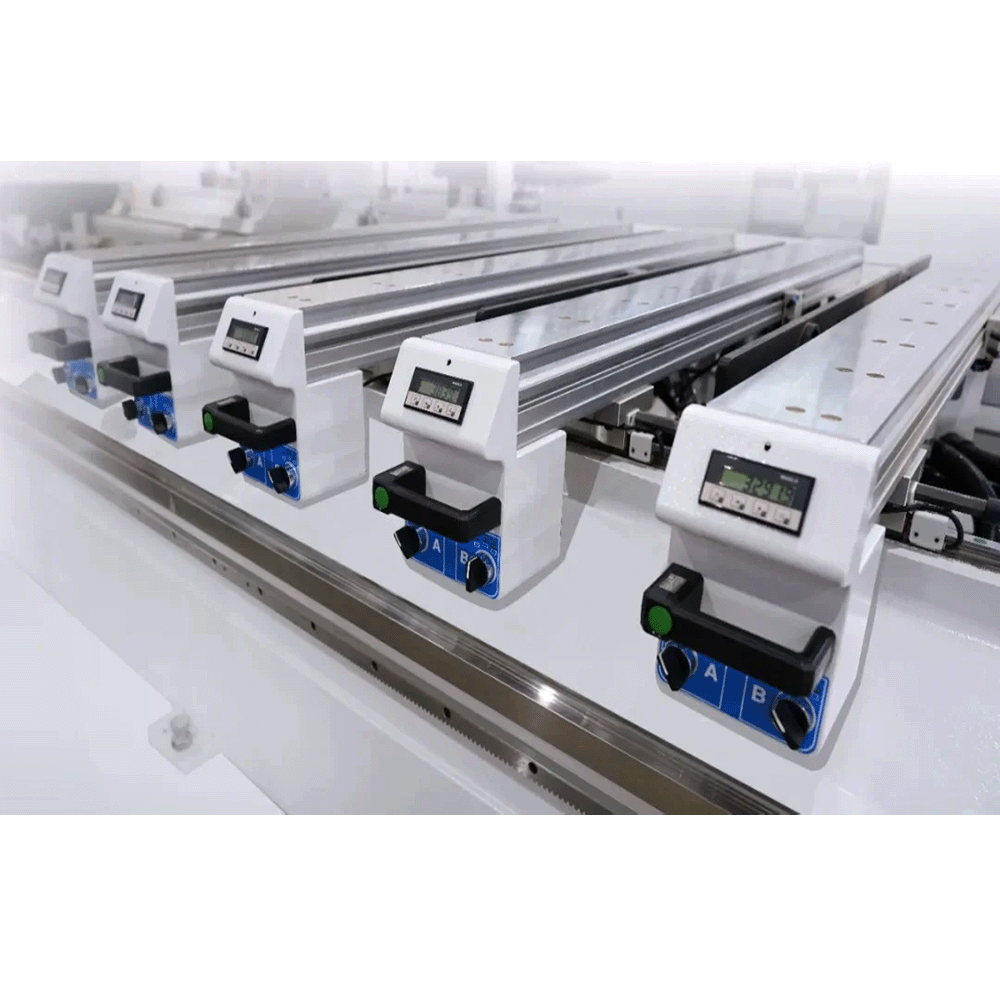

– the counters move along prismatic guides ( THK )

– 20 pneumatic zero points,

– Powerful TPA controller with innovative TPA CAD software

– drilling unit with 20 Protean drills (12 vertical, eight horizontal) and integrated 120 mm saw for 4 mm grooves,

– double X-axis guides – Hiwin gear and rack; along Y and Z axes – TBI endless screw,

– waste conveyor belt,

– remote control included,

– tool length gauge,

– automatic guide lubrication

– X/Y/Z movement speed 80/80/30 m/min,

– DELTA precision servo motors for axis movement,

– dry lamellar vacuum pump BECKER – flow rate 250 m3/h,

– total connection power 29.5 kW

– dimensions of the machine 5930 x 4365 x 3100 mm

– CE safety standards (fence + photocells).