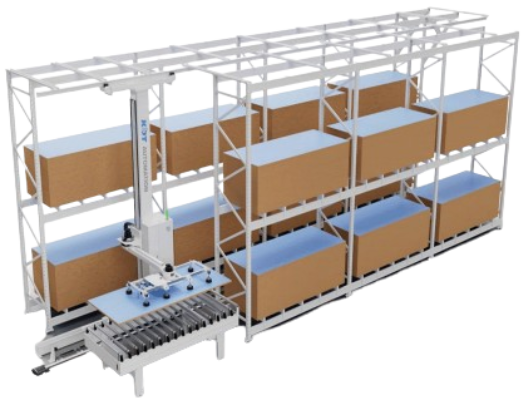

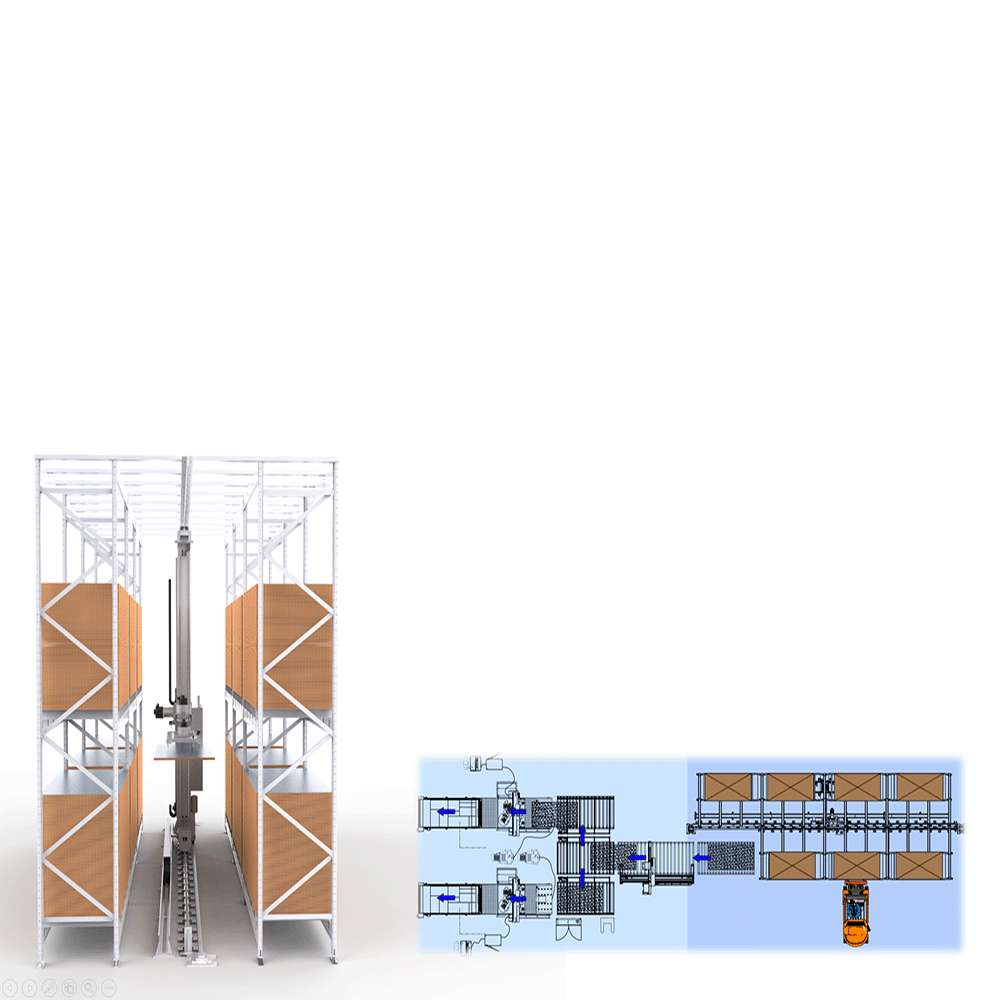

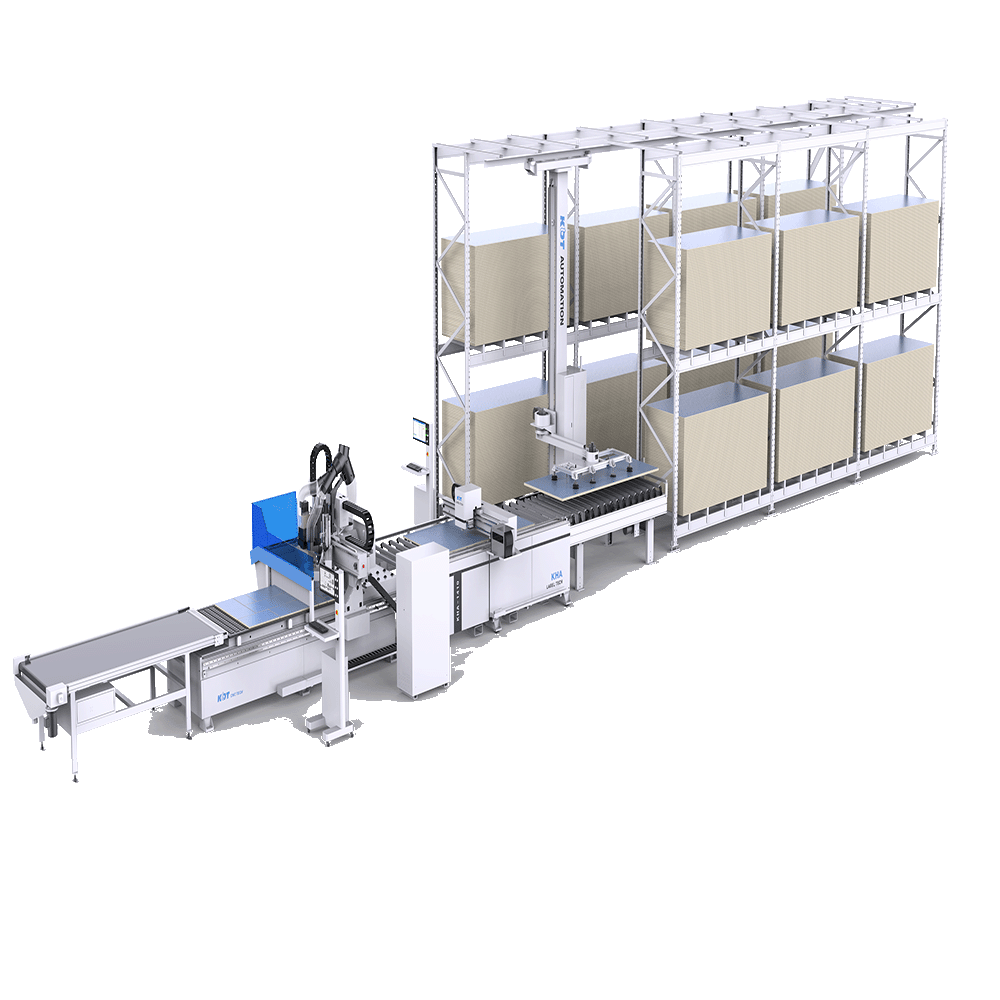

Automated storage is an advanced solution for efficient and reliable management of panel storage in a carpentry workshop. The system is designed to optimize storage space, automate the movement of goods and accurately monitor stocks. Key functionalities include:

- Storage space management:

- Tracking the status of warehouse locations (free, occupied, low stock).

- Easy modification of storage location information and optimization of the height of the supports.

- Automated movement of goods:

- Easy movement of goods with the drag and drop method.

- Possibility of combining storage locations under compatibility conditions.

- Import and export of goods:

- Automated and manual entry of goods with simple search, update and deletion procedures.

- Efficient manual and automatic export of goods, including the possibility of importing data from production plans.

- Robot tasks:

- Conversion of tasks (input, output, transfer) into tasks for the robotic arm.

- Manual update and task control for robotic arm.

- Color management:

- Inventory management of different types of panels for better visual identification of storage locations.

- Reports:

- Detailed reports on inventory status, entries and amounts of goods, with the option of exporting in Excel format for further analysis.

- Settings and log:

- Personalized language and data storage settings.

- Precise logging functionality for debugging and finding anomalies.