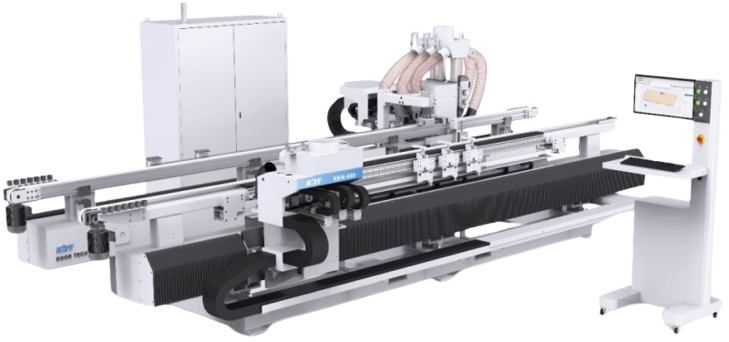

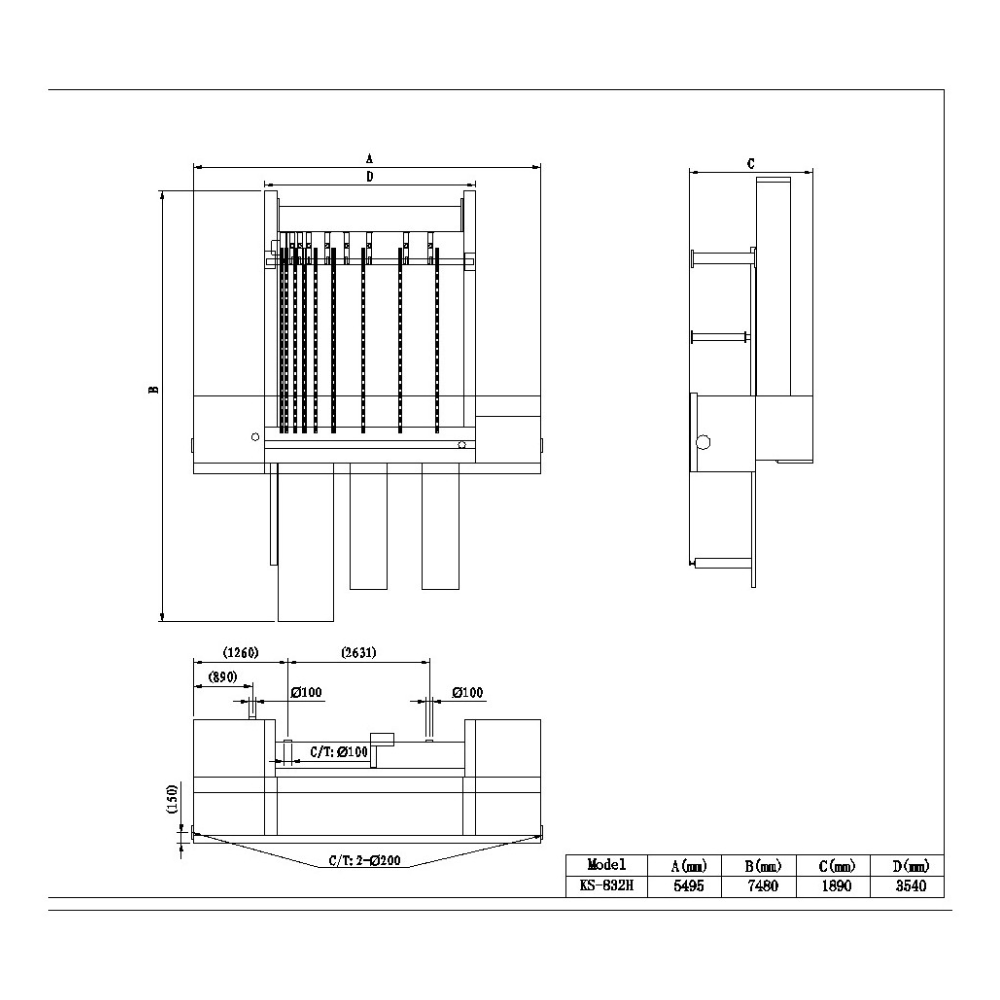

Beam Saw machine KDT KS - 832H

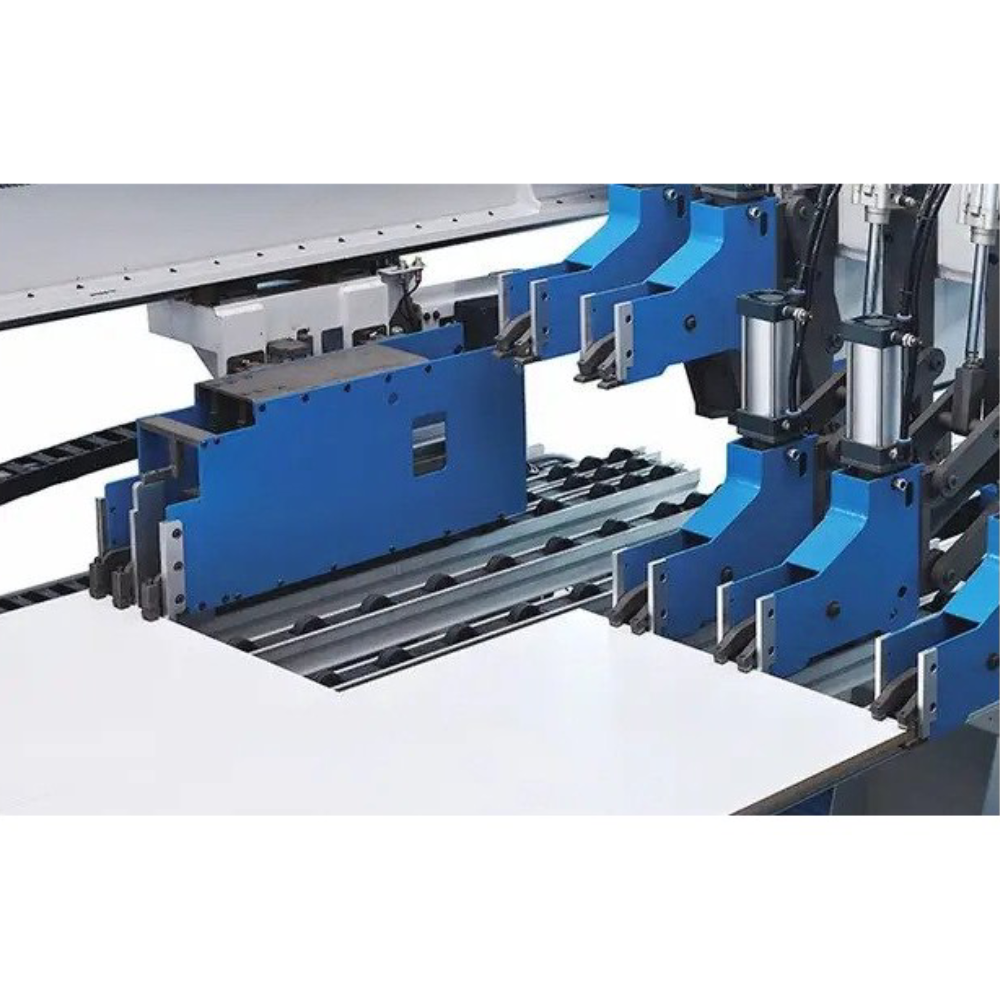

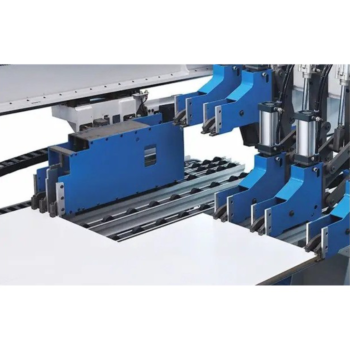

Robust construction that reduces vibrations and enables fast movements. The machine features servo drives for the saw aggregate for maximum acceleration and deceleration and quick return of the aggregate to the initial position. Not just speed.Air table in the cutting area enables high-quality cutting of more sensitive materials and easier sliding of heavier workpieces. The side press is NC controlled and is faster than conventional pre-rotating presses. A magnetic strip ensures a high accuracy of 0.1 mm.

Entry air tables enable easy sliding of workpieces. The possibility of moving the work table left and right is an additional solution that can make the work easier for the user.

The height of the saw is automatically adjusted according to the height of the workpiece. This enables the optimum blade height regardless of the height of the workpiece and consequently the best cut quality. The quick change of the circular saw blade improves the efficiency of the saw itself.

While most of the well-known manufacturers install valuable Touchscreen screens, KDT cutters KDT are equipped with classic industrial PC computers in the Windows environment, which are very stable, affordable and easy to maintain, and especially wallet-friendly in in case of malfunctions. Effective machine management is ensured by the powerful and user-friendly KDTsoft software, which also includes effective cut optimization and good yield.

Technical characteristics and equipment of the machine

- Cutting height 90 mm

- Cutting 3100 x 3200 mm

- Max. circular saw blade diameter 400 mm (bore 75 mm)

- Max. pre-cut diameter 200 mm (bore 50 mm)

- 10 pneumatic pliers - each pliers has 4 fingers or grasped

- Cutting speed 1-95 m/min, SERVO feed motor

- Moving speed of the saw unit up to 120 m/min

- Plier bridge movement 1 - 95 m/min

- PC computer with Windows environment

- Modern software with optimization

- Barcode printer

- Main engine power 15 kW

- Pre-cutter motor power 1.5 kW

- Precut independently adjustable

- Moving the saw unit via a servo motor, gear and toothed rack for fast movements

- 3x air table with sliding rollers at the entrance

- Air table in the cutting area for better processing of smaller pieces

- Motorized NC controlled lateral press stroke 2200 mm

- Machine dimensions 7480x5495x1890

- Robust industrial construction - machine weight 6000 kg