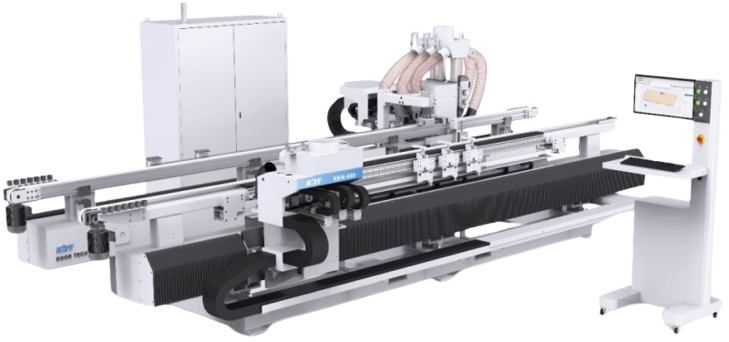

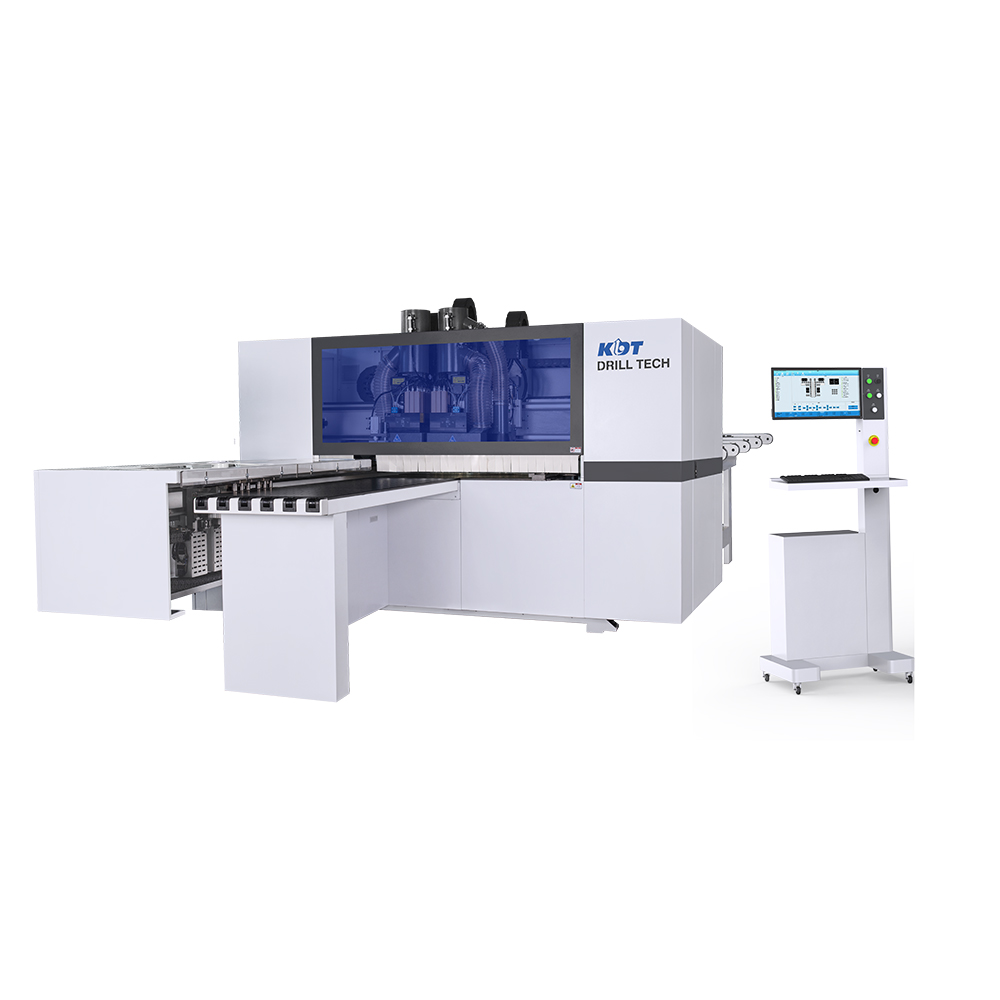

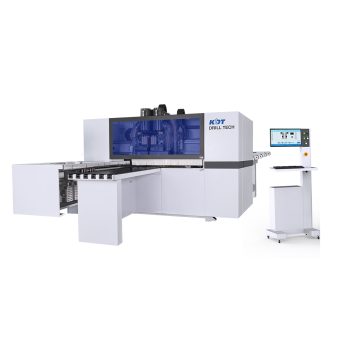

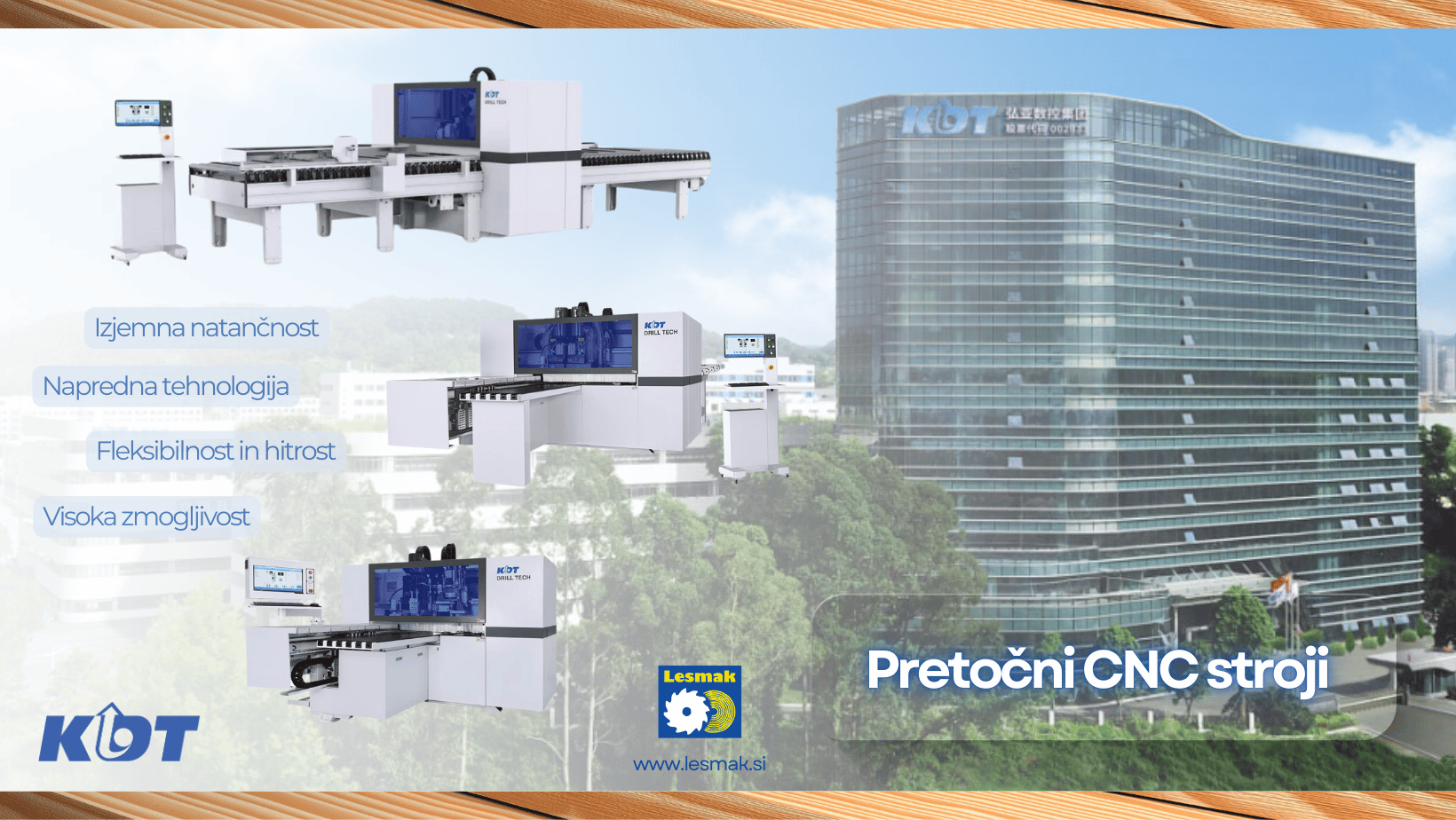

Main features of KDT KD-612G Drilling/Routing CNC machine

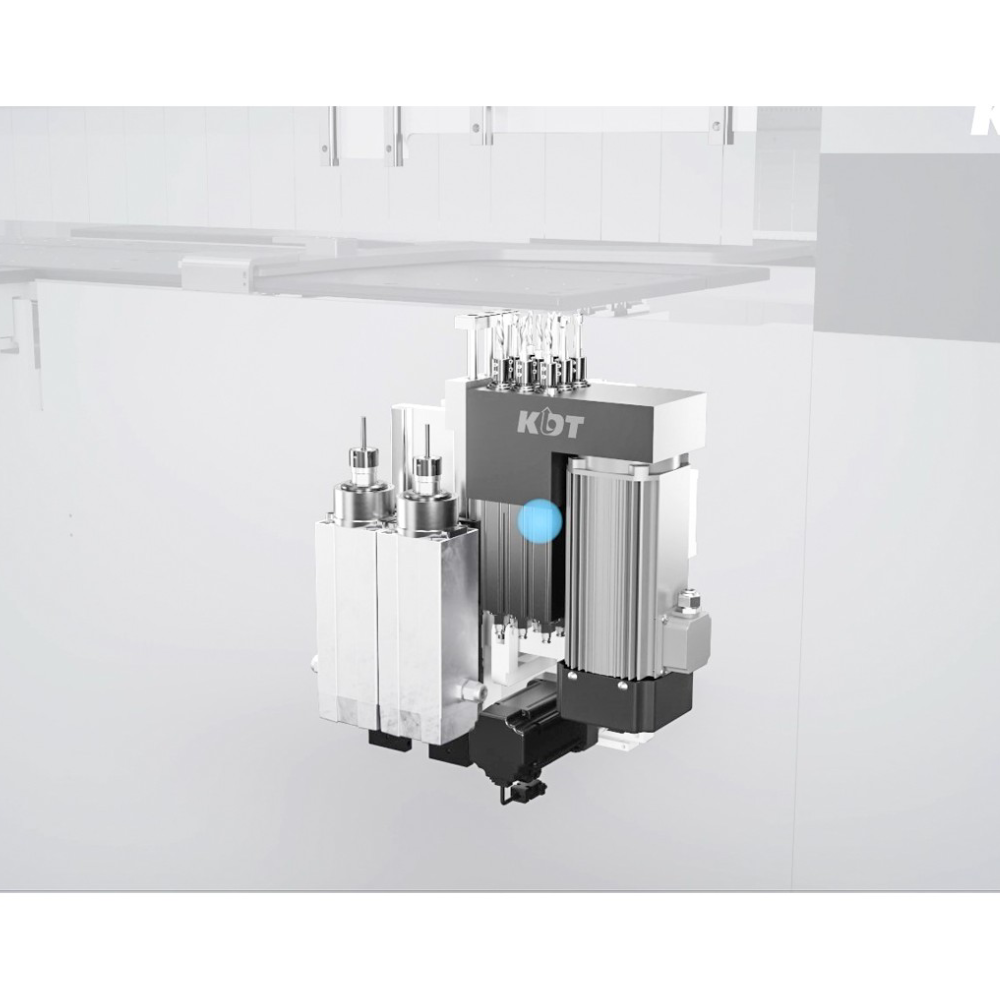

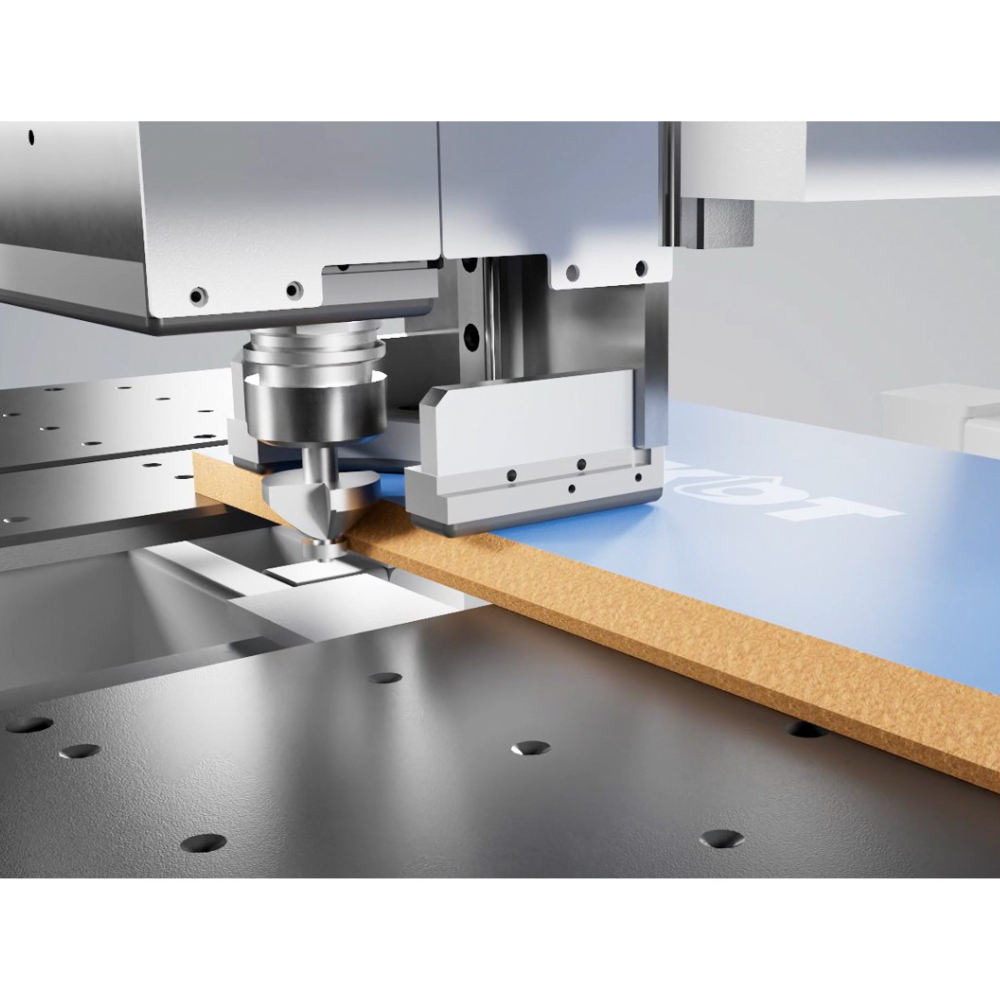

- Six-sided drilling and milling: Machining capability on all six sides with two drilling groups and 4 milling units.

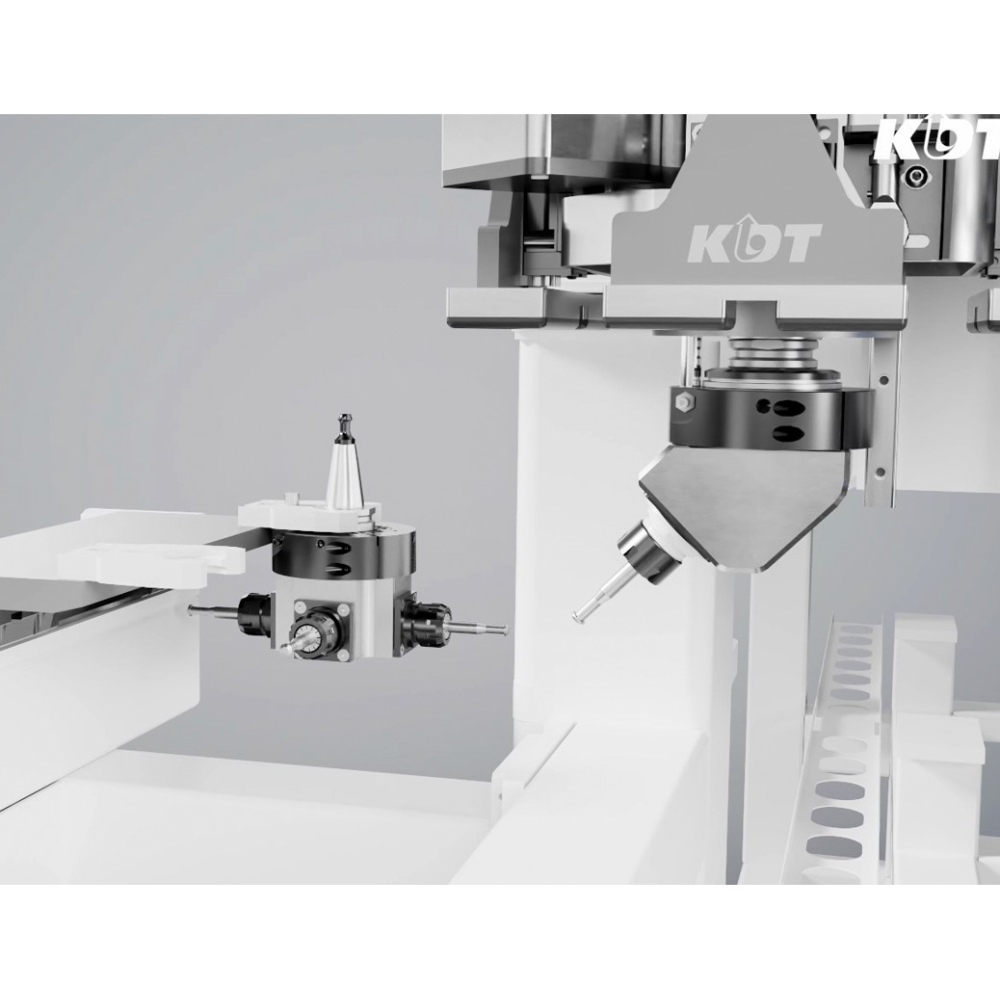

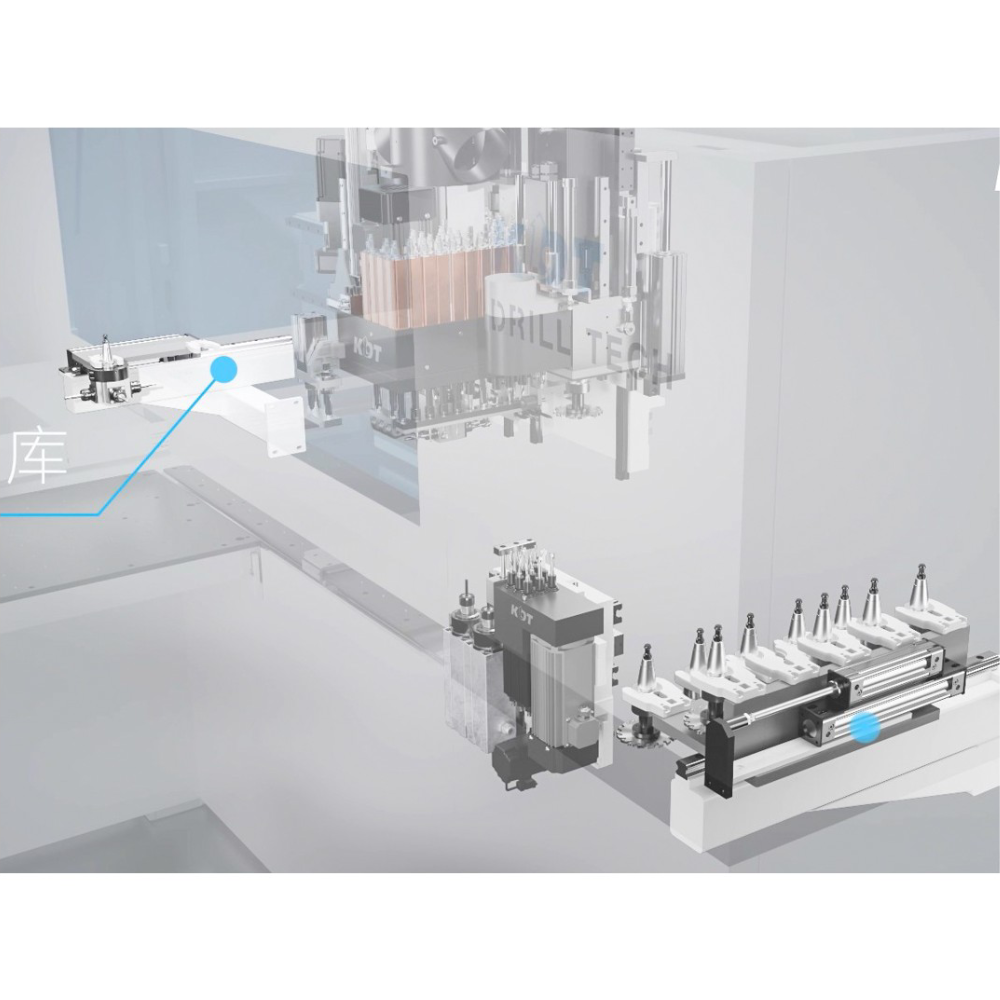

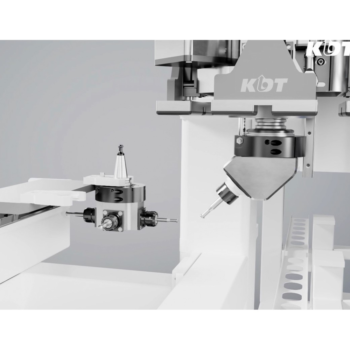

- Automatic tool change: The 4-axis unit has the option of simultaneously changing two corner units on the left side, and on the right side it has an additional milling unit with a magazine for up to 10 tool positions.

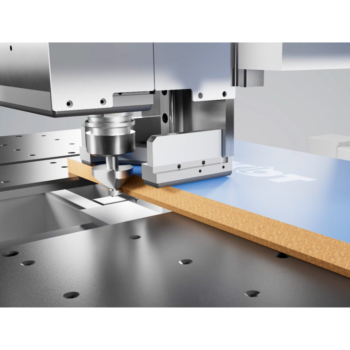

- Multipurpose use: Enables all operations from drilling, milling, sawing with the smallest workpiece 70x35 mm and a maximum width of 1200 mm.

- High speed and precision: Maximum X/Y/Z axis speed 140/90/50 m/min and high precision.

Additional Functions - Machine KDT KD-612G

- Multifunctional 4th C os: Enables working with many different corner aggregates and processing in one cycle without re-positioning.

- High quality servo drives: Use of precision INVT servo drives for exceptional accuracy and productivity.

- Intelligent dust and residue removal system: Automated removal of residues and dust for a clean working environment.

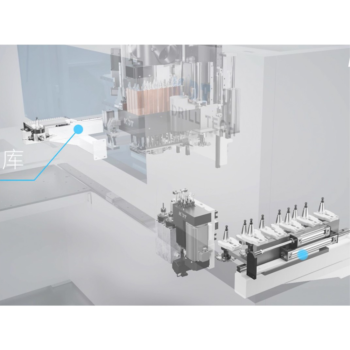

- Support for connectivity with other programs: Compatibility with various programs for optimizing production and using barcodes.

The CNC machine is ideal for:

- Production of unique furniture or production of more demanding elements

- High precision manufacturing of complex components.

- Automation and improvement of efficiency of production.

KDT is a guarantee for the highest quality machines and services. The KD-612G is a reflection of our commitment to innovation and excellence.