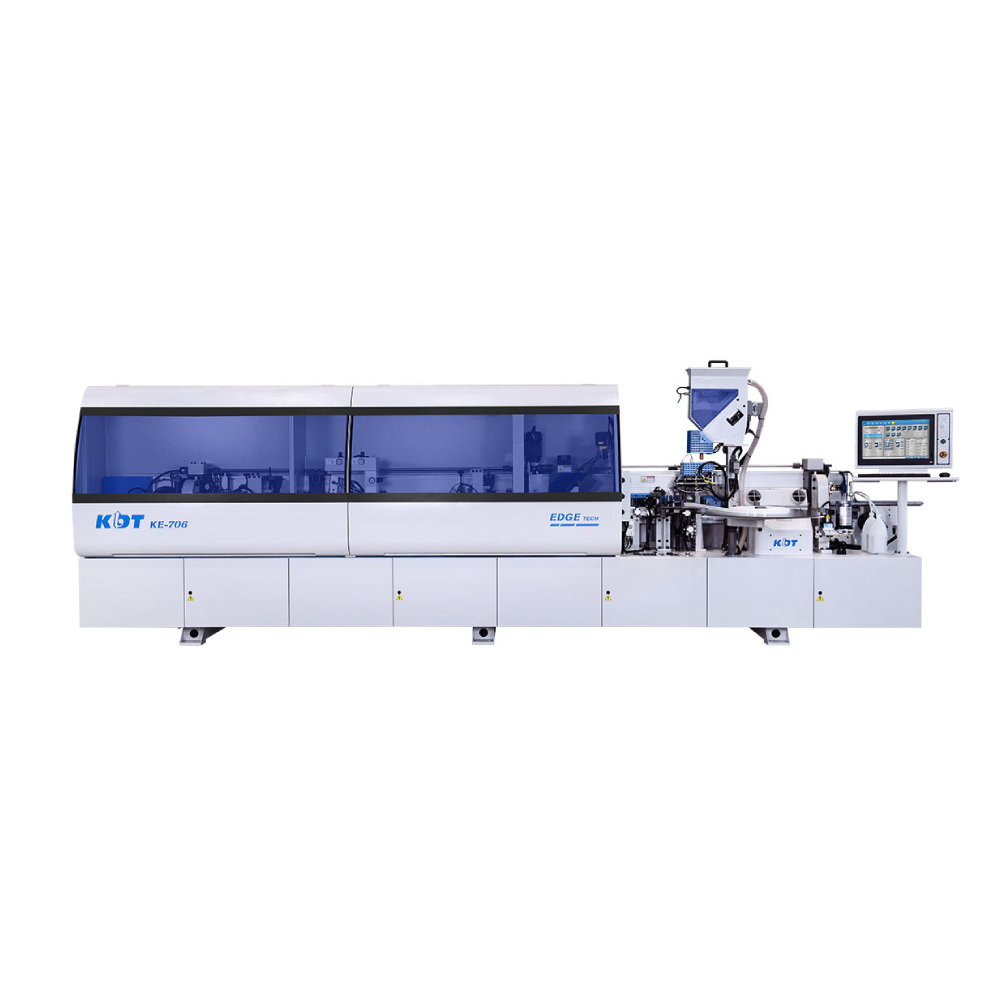

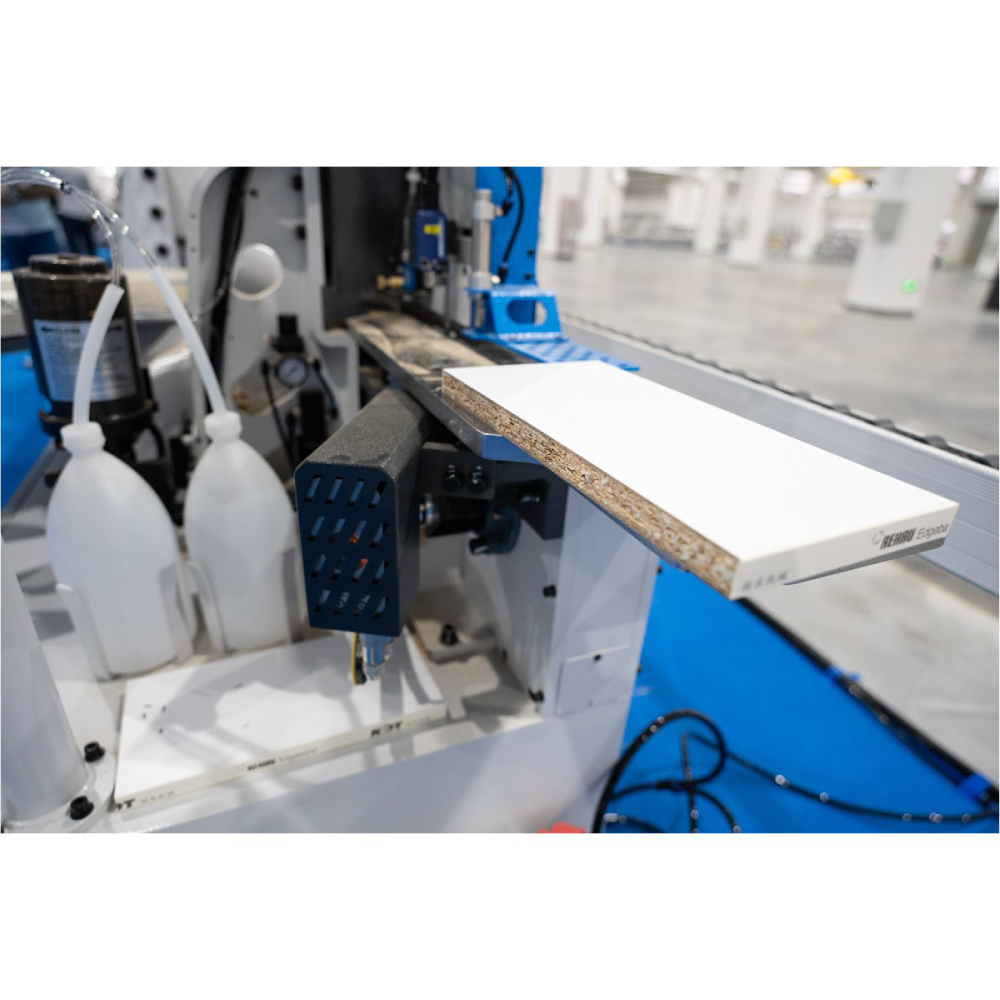

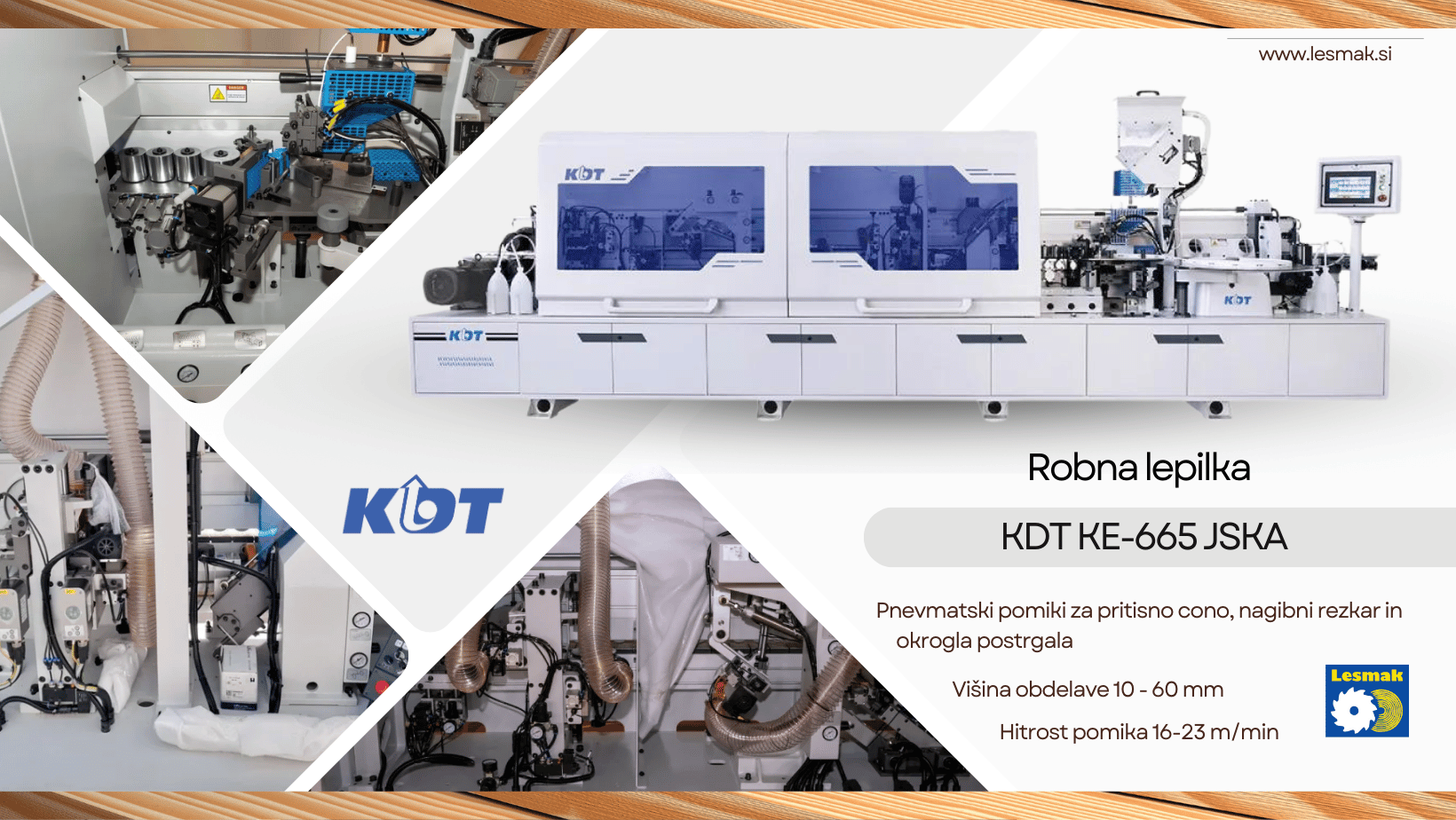

Edge Bander KDT KE-706

Due to its compact size (5.8 m length), it is suitable for both small and large companies. Its above-average productivity and reliability are the result of robust construction and industrial components, which enable continuous operation - 24 hours a day, 7 days a week - while maintaining high quality standards.

Work aggregates include

- DIA pre-milling machines,

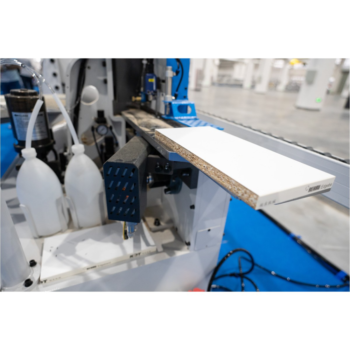

- glue application,

- pressure zone with 5 rollers,

- cheers,

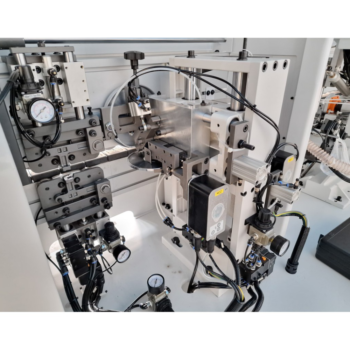

- tilt cutters,

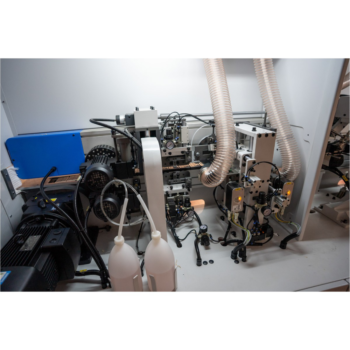

- rondomat with two motors,

- round and flat scrapers,

- brushes,

- application of liquids.

The basic characteristics of the machine are:

- Moving speed between 12 and 18 m/min,

- Servo drives for pressure zone, tilting cutter and round scrapers,

- Option to choose between two different radii (1 and 1.5 mm or 1 and 2 mm),

- Industrial PC,

- Intuitive software with 12 work programs for quick and easy use,

- Working height between 10 and 60 mm,

- Dimensions: 5850 x 940 x 1960 mm, weight: 2500 kg.

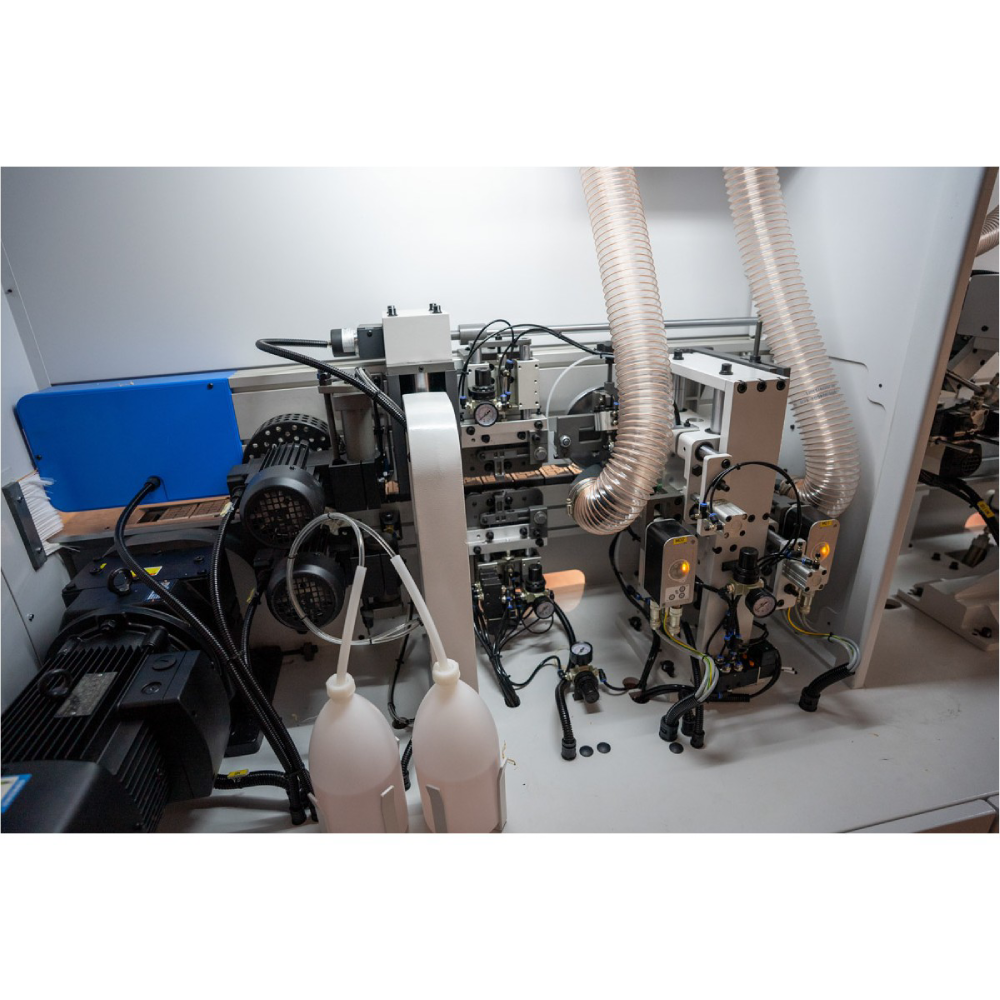

Advantages of industrial construction

Thanks to the monolithic and rigid construction, which is designed with advanced 3D design tools, the machine provides exceptional stability and enables continuous operation. KDT uses state-of-the-art manufacturing technologies, including selection of high-quality materials, robotic welding, artificial aging to eliminate structural stress, and machining on state-of-the-art CNC machines. This ensures reliable operation without the need for constant adjustments.

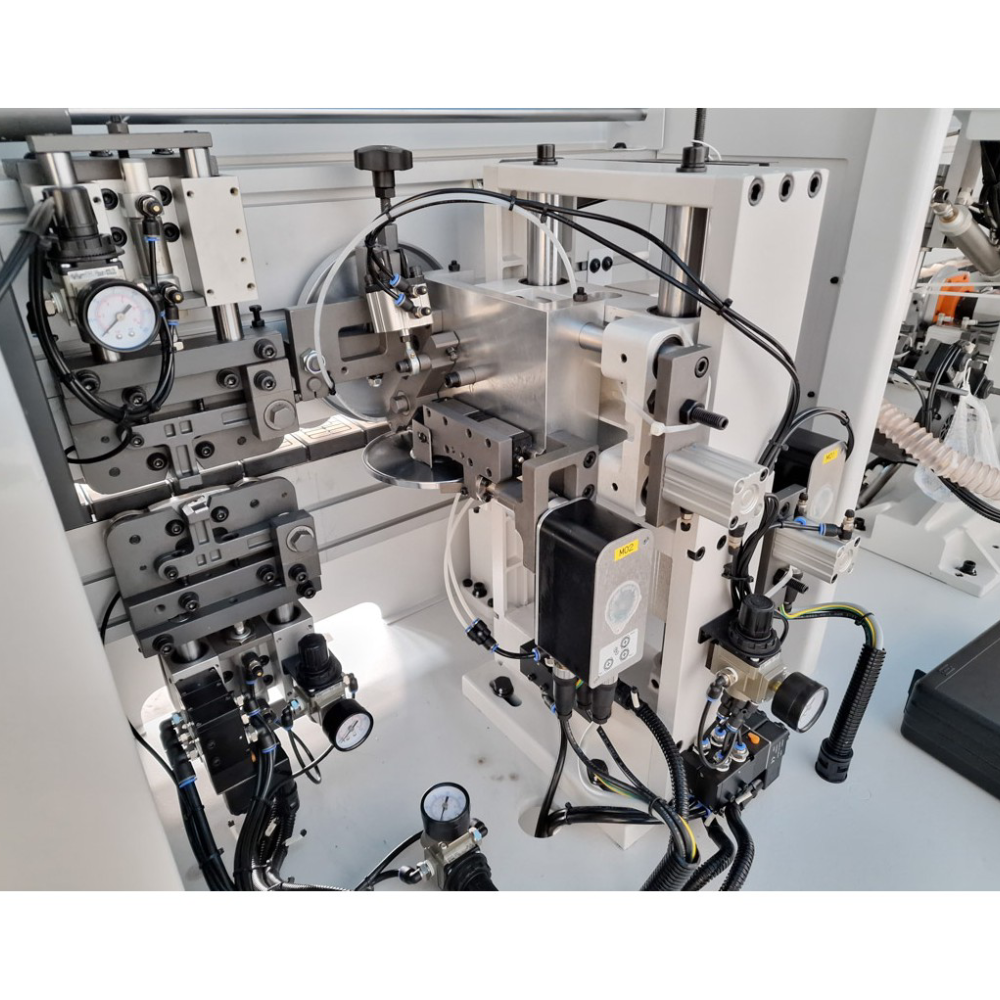

Premium glue pot

The advanced glue kettle enables easy use of EVA and PUR glues and automatic glue change with an additional chamber for storage, maintenance and pre-heating. This enables a quick change of adhesives (within 2 to 3 minutes) without wasting time, ensuring fresh adhesive and high-quality joints.

Premium glue pot

The advanced glue kettle enables easy use of EVA and PUR glues and automatic glue change with an additional chamber for storage, maintenance and pre-heating. This enables a quick change of adhesives (within 2 to 3 minutes) without wasting time, ensuring fresh adhesive and high-quality joints.

Drive belt instead of wheels (option)

The optional drive belt reduces contact and the possibility of dust sticking to the workpieces, which is especially useful on sensitive surfaces.

Effective dust removal

The machine comes standard with larger diameter dust removal attachments for better removal.

Two different liquid application units

For optimal final results, the machine uses the application of a separating and cleaning agent that prevents sticking and increases the efficiency of brushes and scrapers.

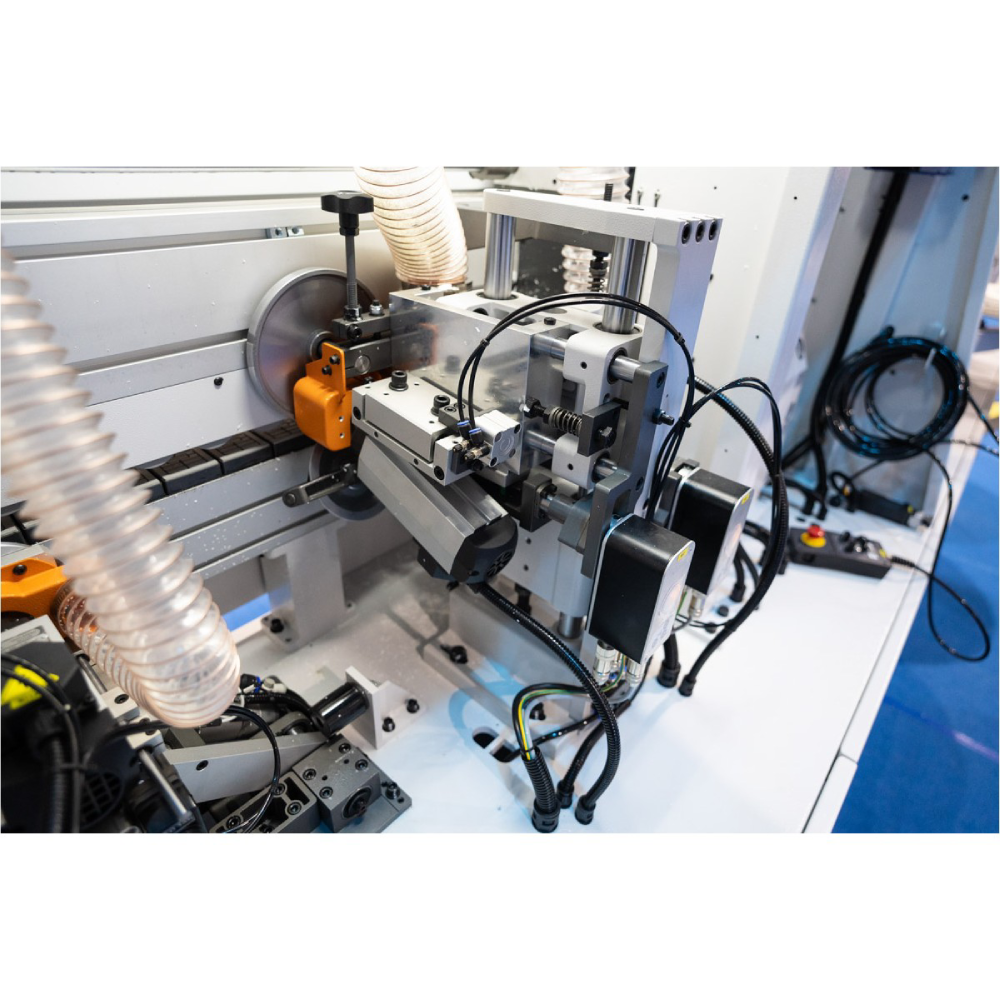

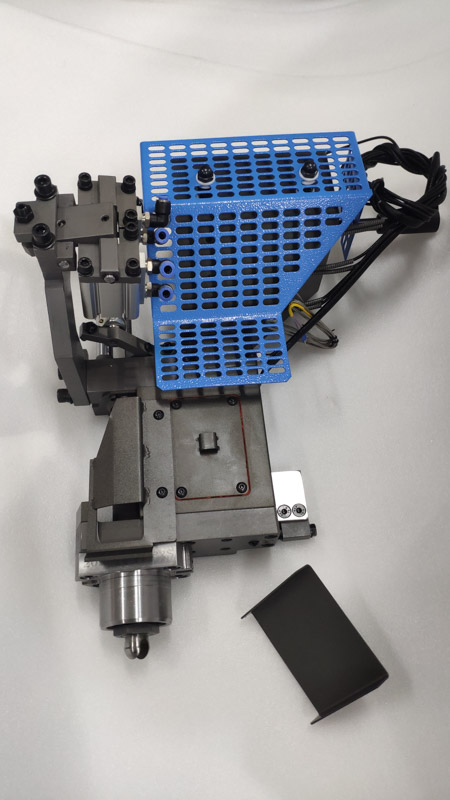

Double rondomat for perfectly finished corners

With two high-frequency motors and pneumatic adjustment, the rondomat enables the processing of four different profiles, ensuring optically perfect corners without the need for manual corrections.

Round and flat scrapers for a superior finish

Due to stability during processing, large diameters of copying wheels and effective dust removal, industrial scrapers provide better results than most machines on the market.

Premium glue kettle KDT

Easy emptying of the kettle with an automatic cycle. Very suitable for EVA and PUR adhesives. In combination with a vacuum chamber, the possibility of pre-heating the glue, so that it is possible to change the glue and continue work immediately.