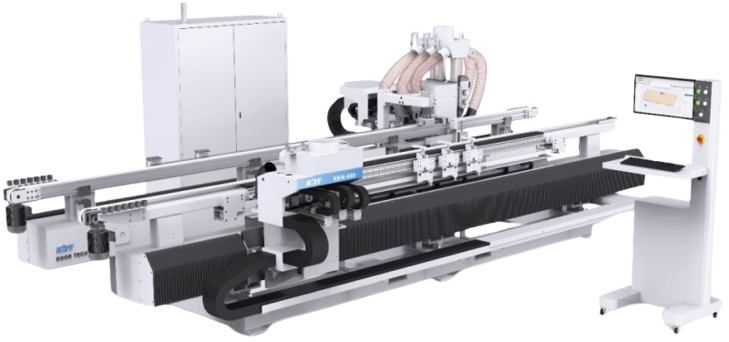

Drilling/Routing CNC machine KDT KN-612 KHSA

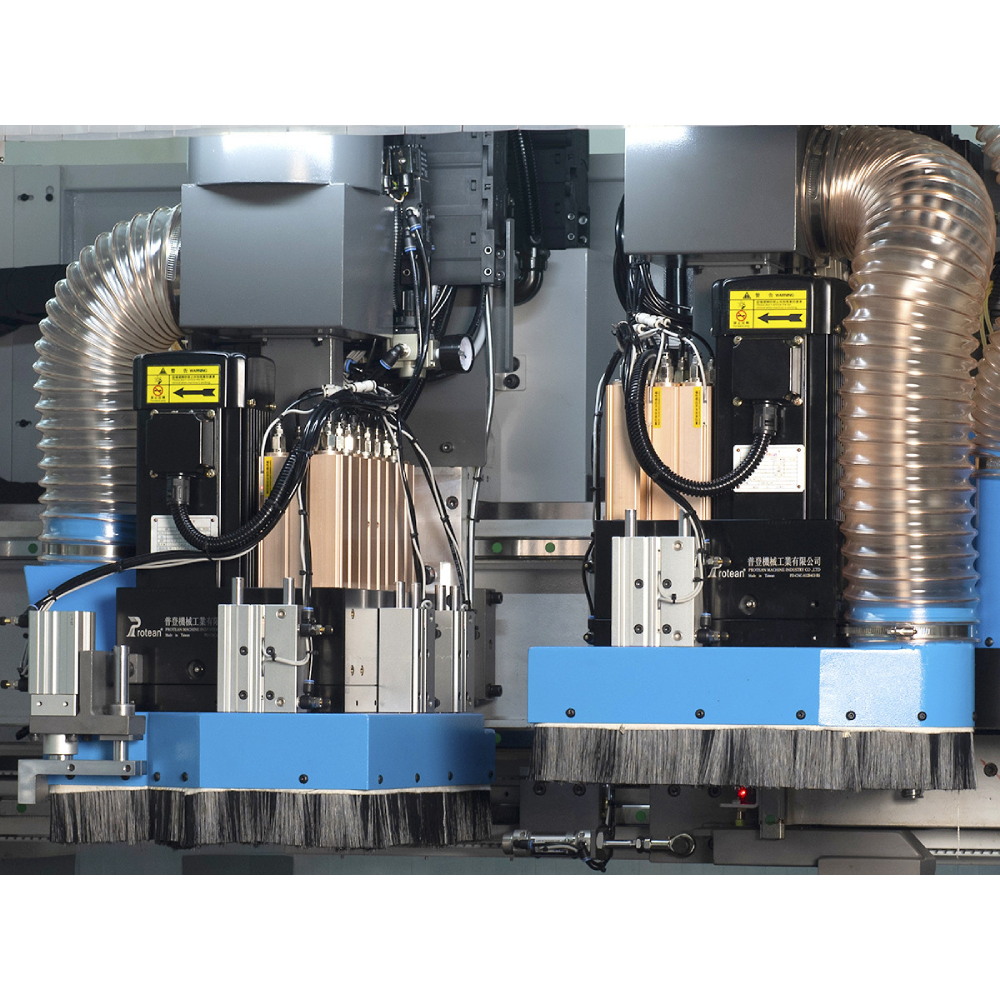

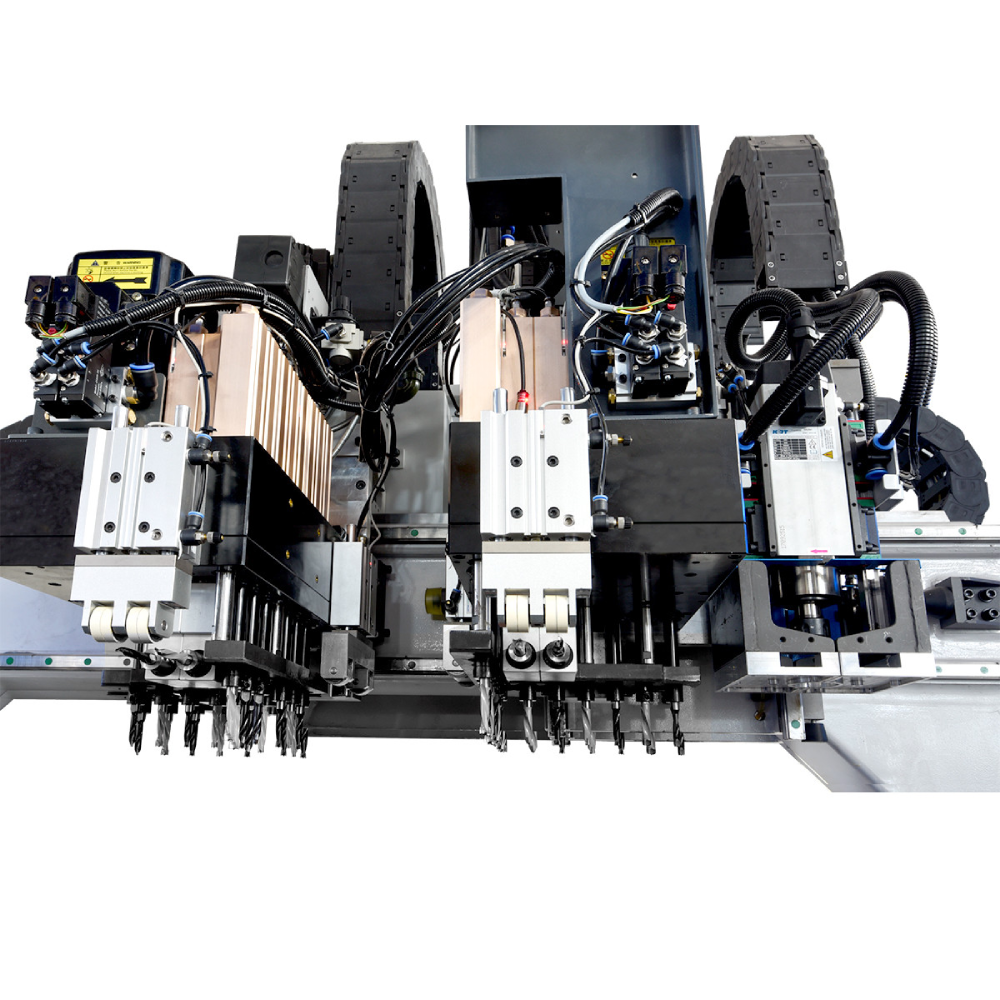

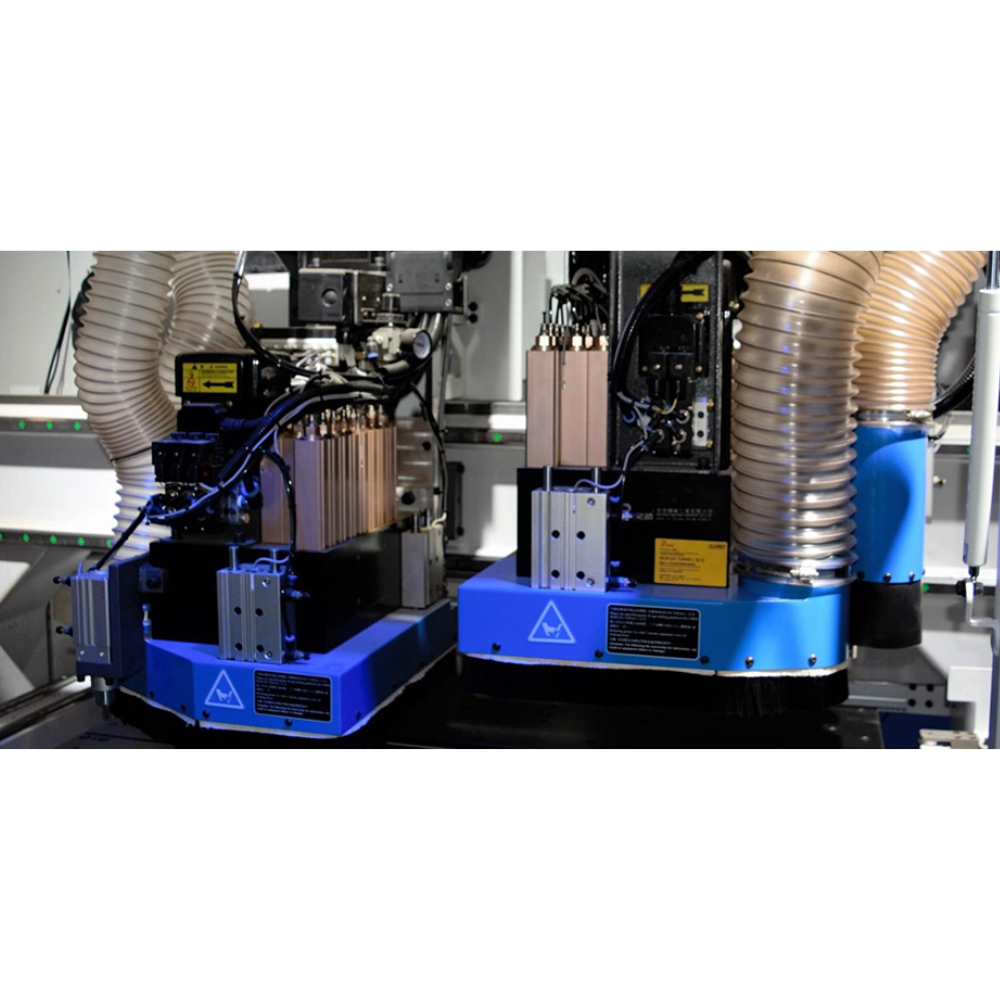

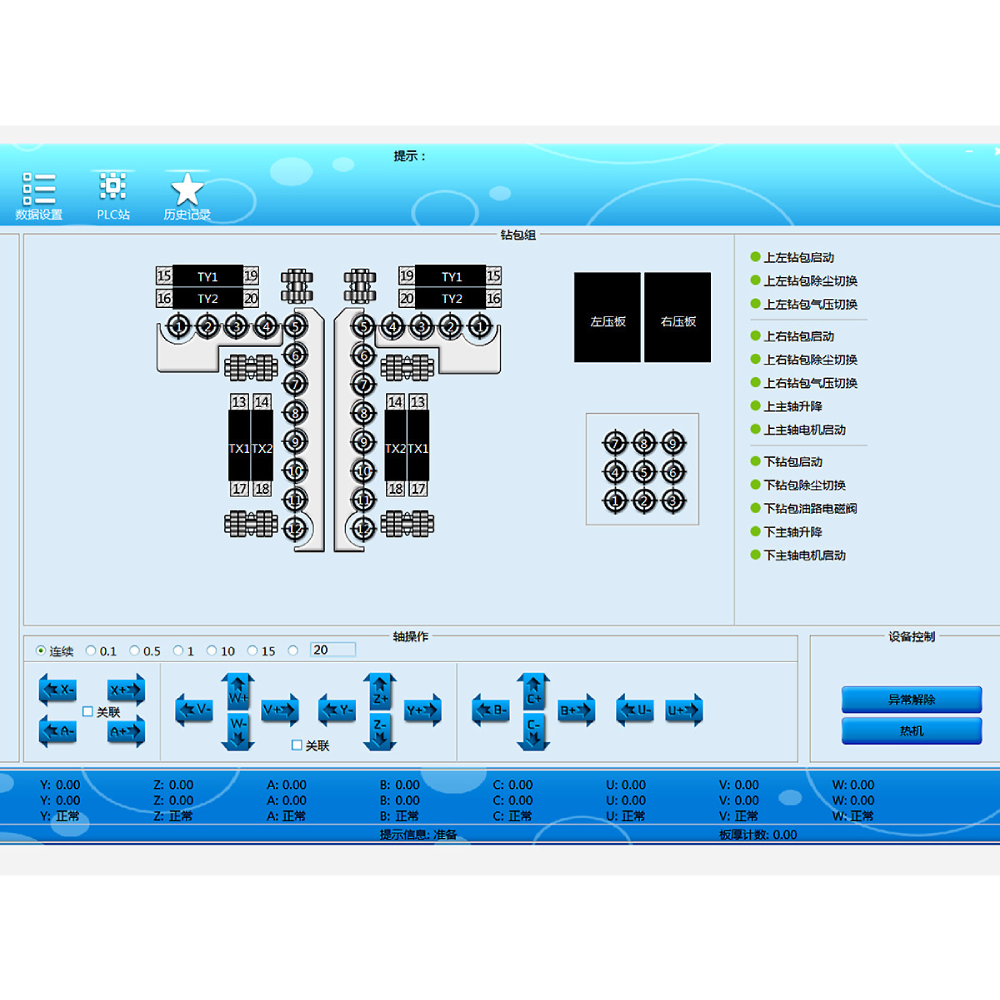

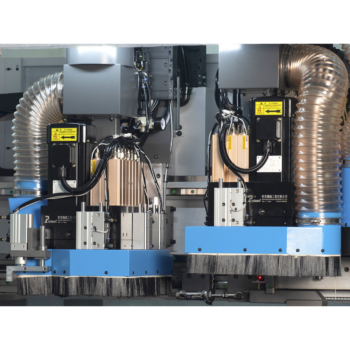

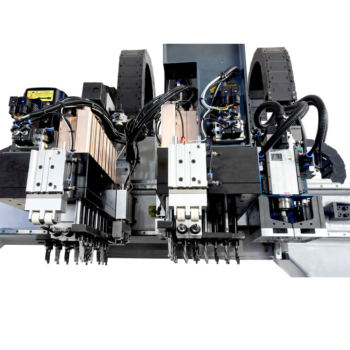

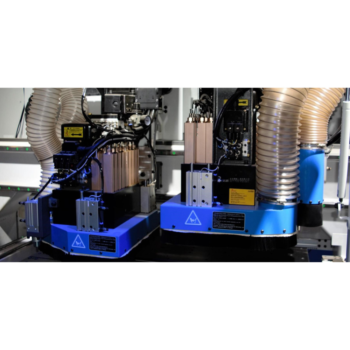

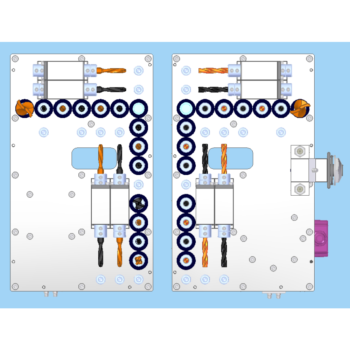

The CNC KDT KN-612 KHSA flow automatic machine is an extremely productive CNC drilling and milling machine with three independent drilling heads for more efficient work and greater productivity, and two milling aggregates (5 kW and 3.4 KW). The machine is equipped with two independent drilling headswith 18 + 18 drills above and one drilling unit with 9 drills below.

Features of the KDT KN-612 KHSA machine

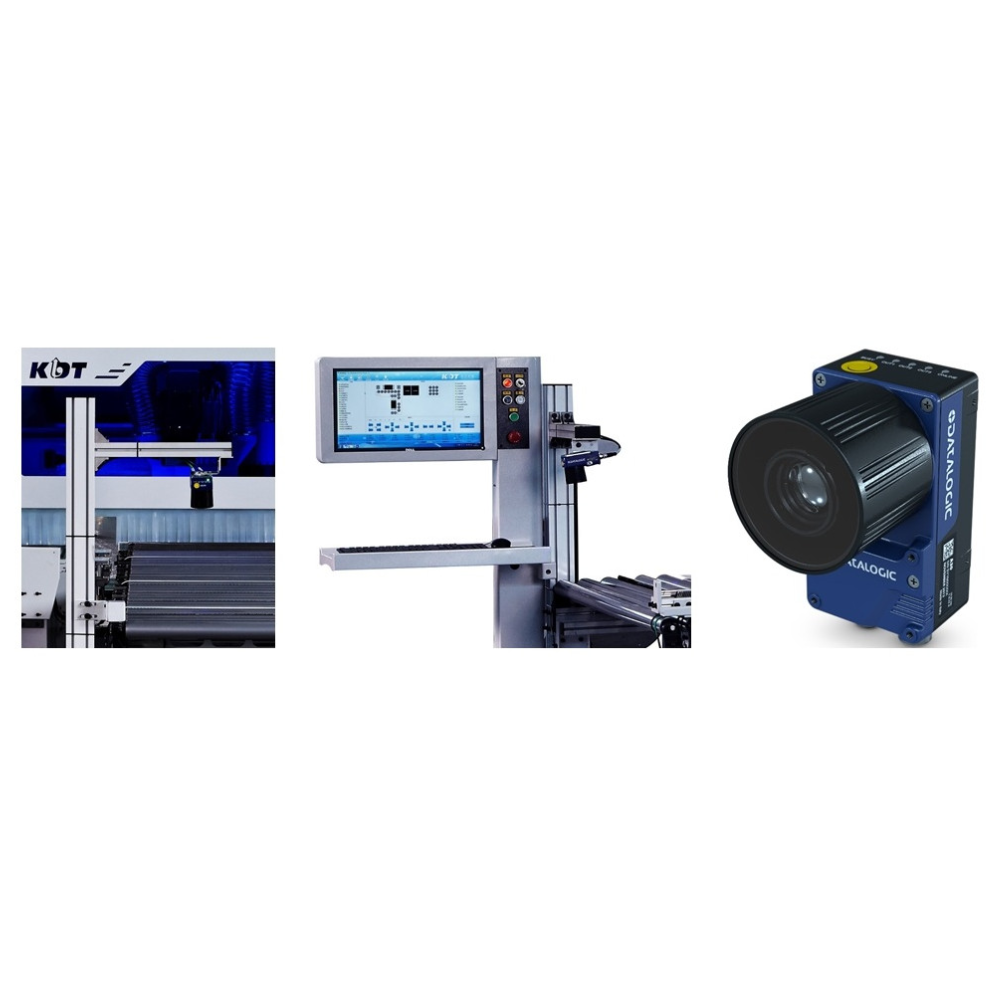

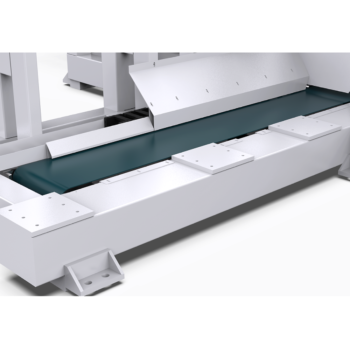

Roller transport device enables the automatic movement of workpieces into and out of the machine. The QR scanner (Datalogic optics system) is installed at the entrance, on the bracket. It automatically scans each piece and activates a certain program for processing the workpiece. This saves a lot of time and energy and significantly increases productivity.

The machine does not require any additional user activation during processing. Everything is automatic.

Processing capacity up to 210 workpieces/hour orfrom 720 to 1680 workers per work shift (8 hours).

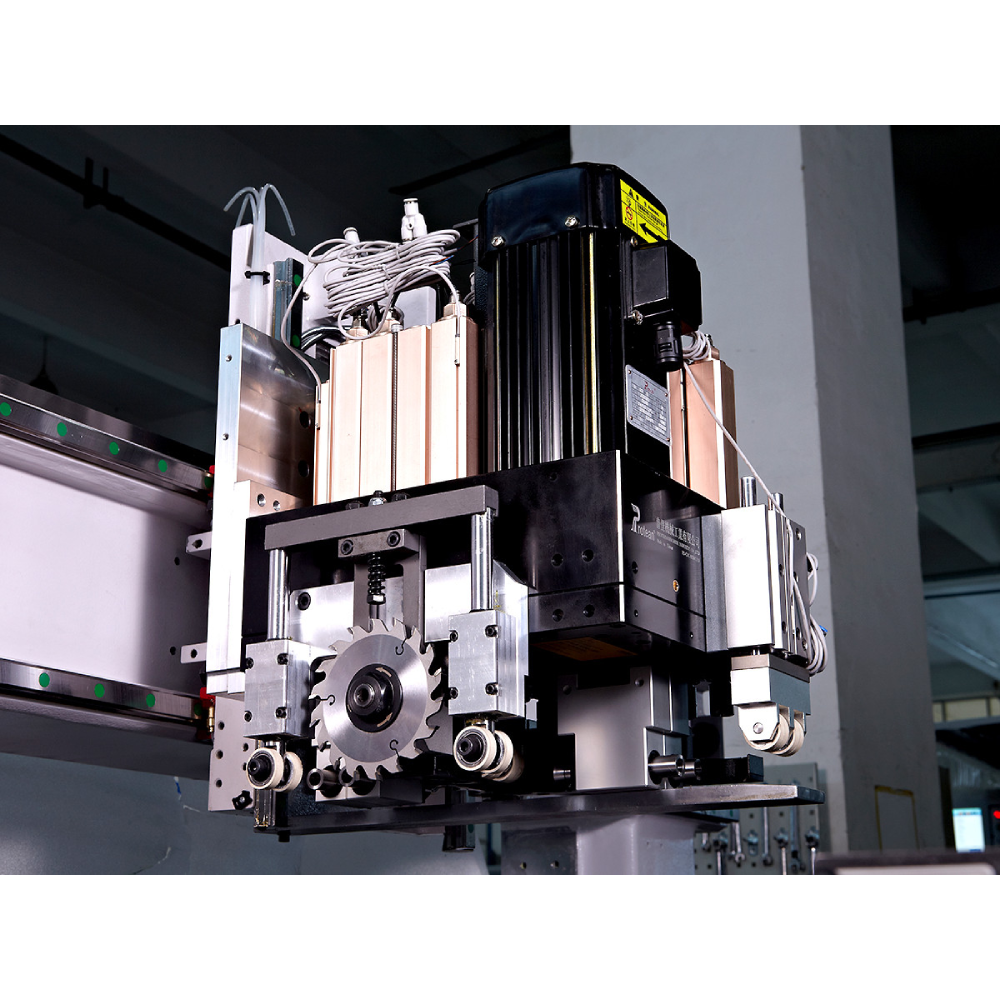

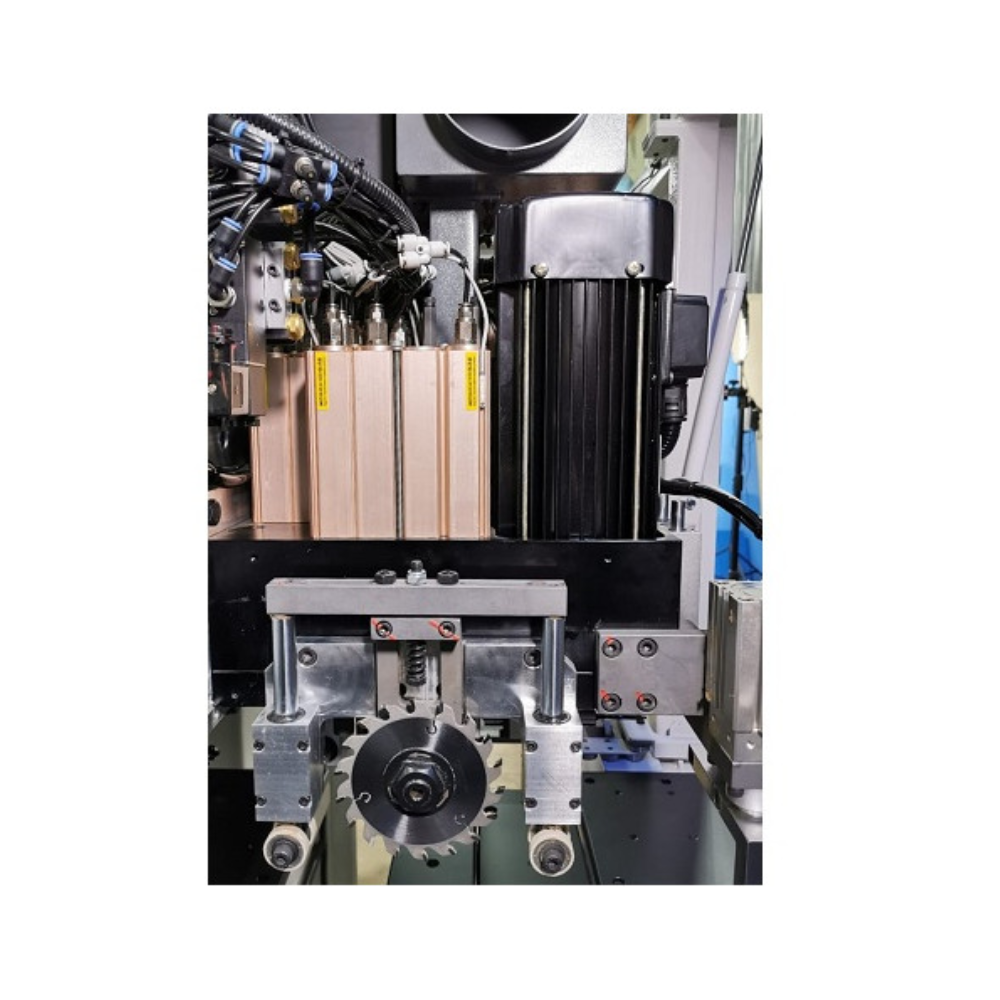

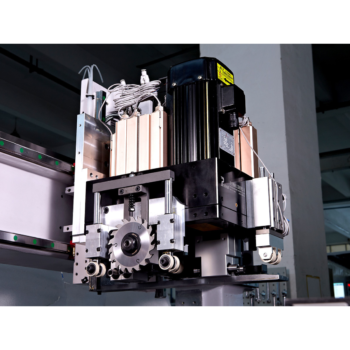

The top drilling unit has an integrated back slot saw.

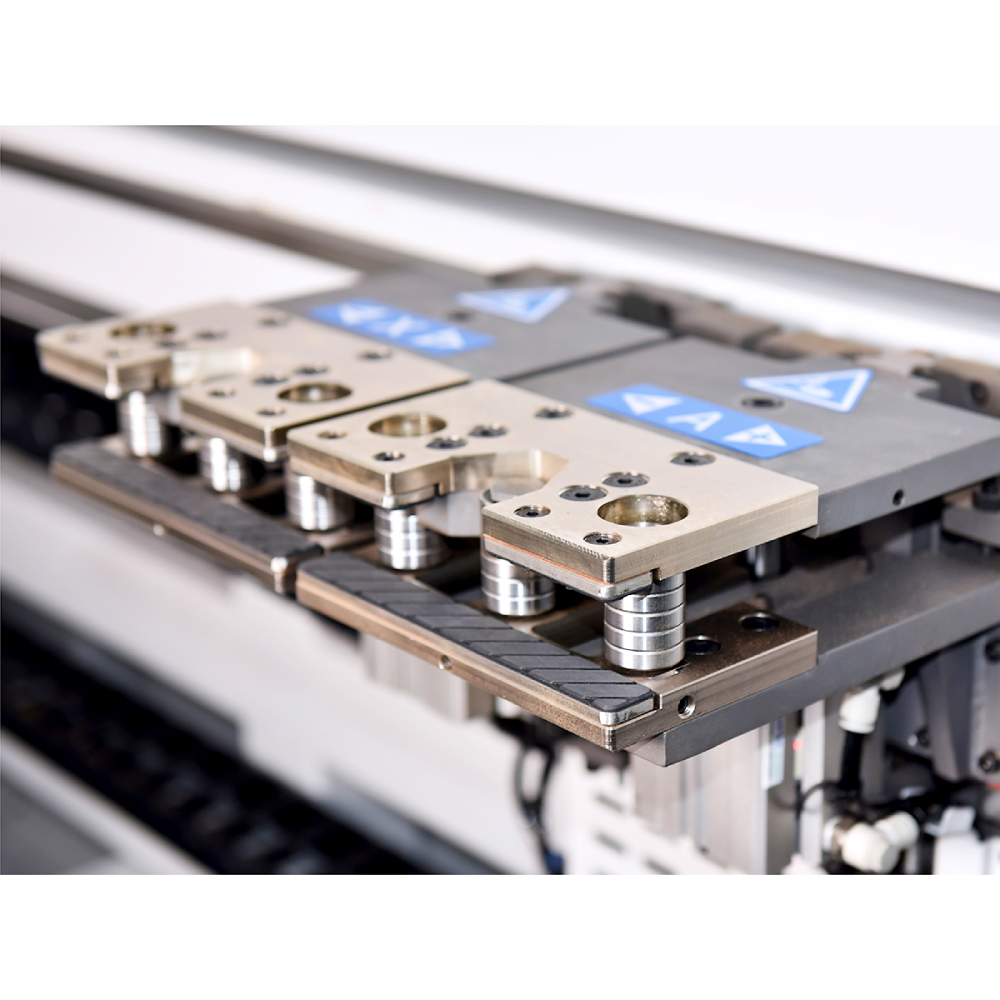

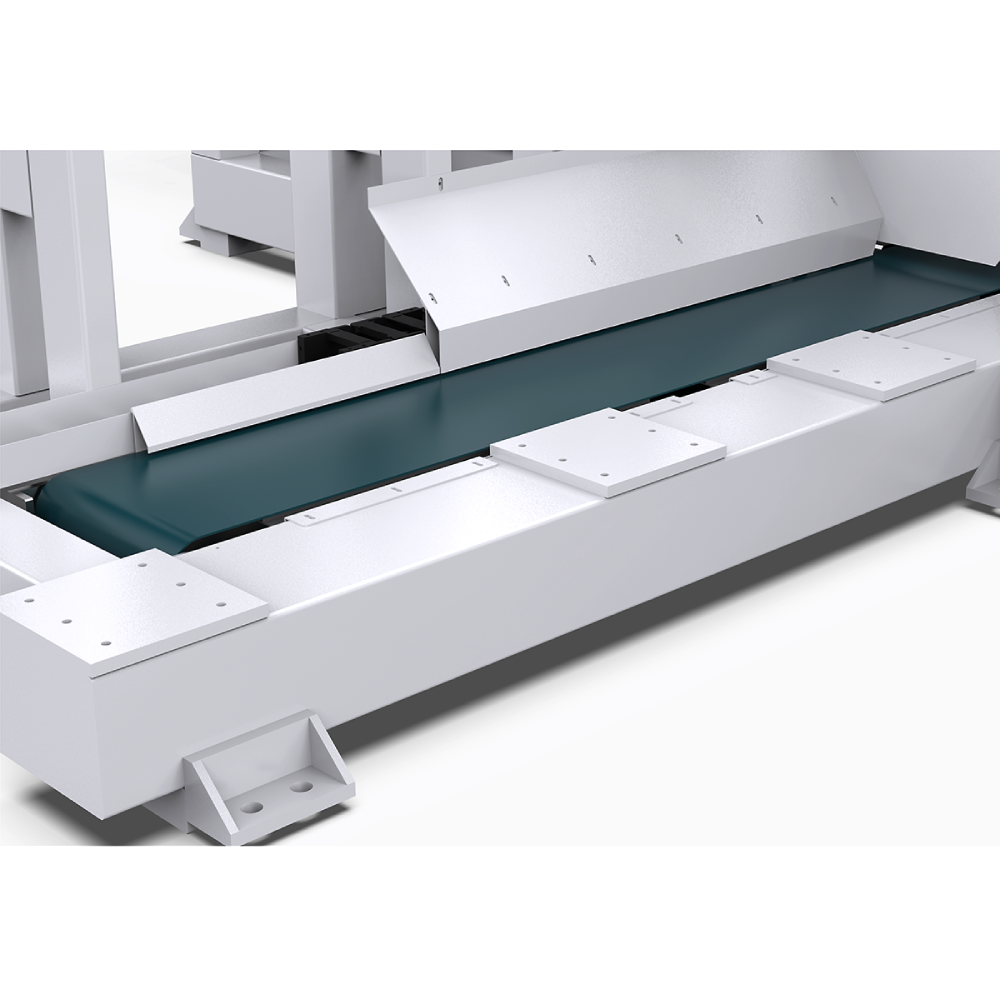

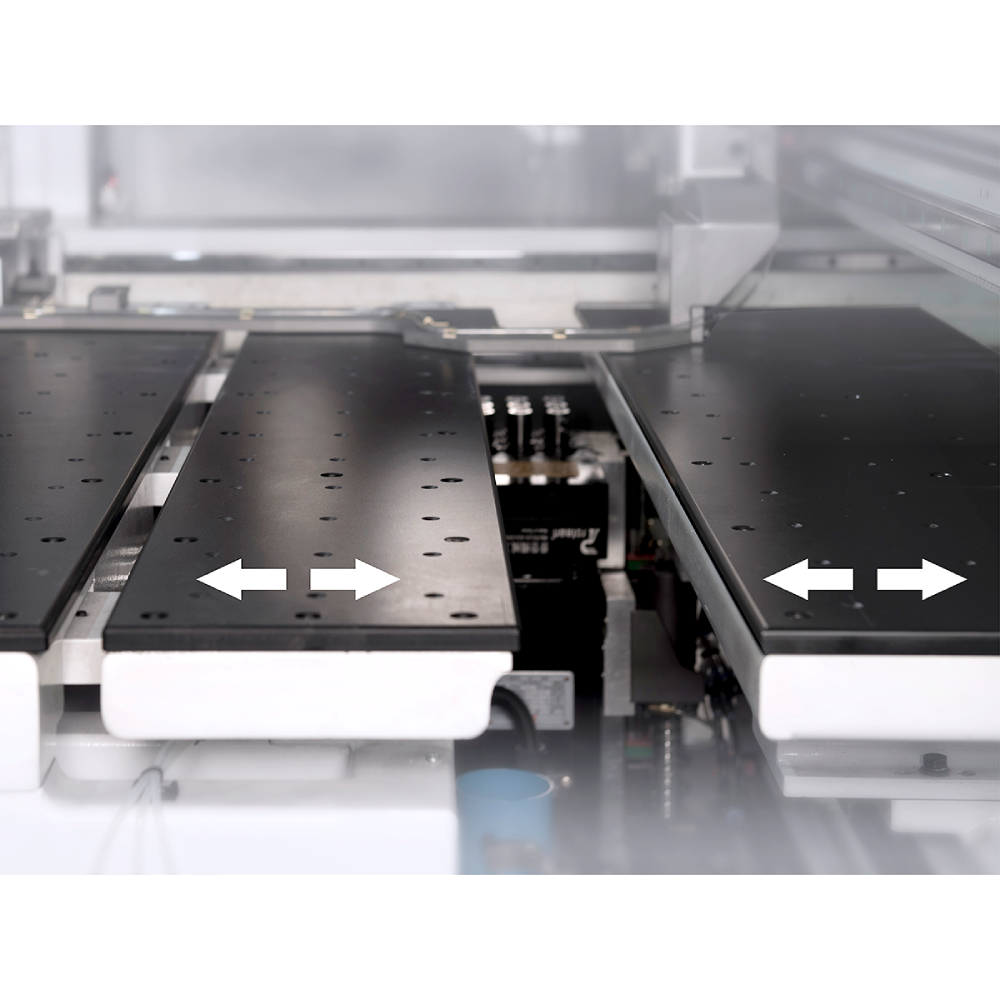

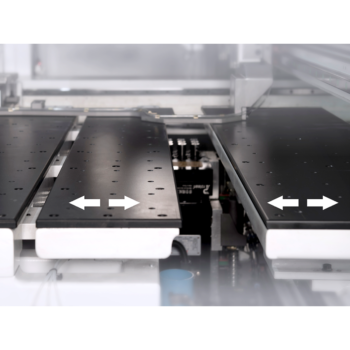

The machine is equipped with a pair of independent pliers and automatically detects holes to avoid the pliers from getting caught. The length of the pliers guides is 5500 mm for processing long pieces without gripping the pliers. Double air worktable for easier movement of workpieces, especially workpieces with a sensitive surface.Double pliers for faster work and more precise gripping. Conveyor belt for moving waste material from the machine.

The moving speed of the pliers is 140 m/min, which is exceptional.

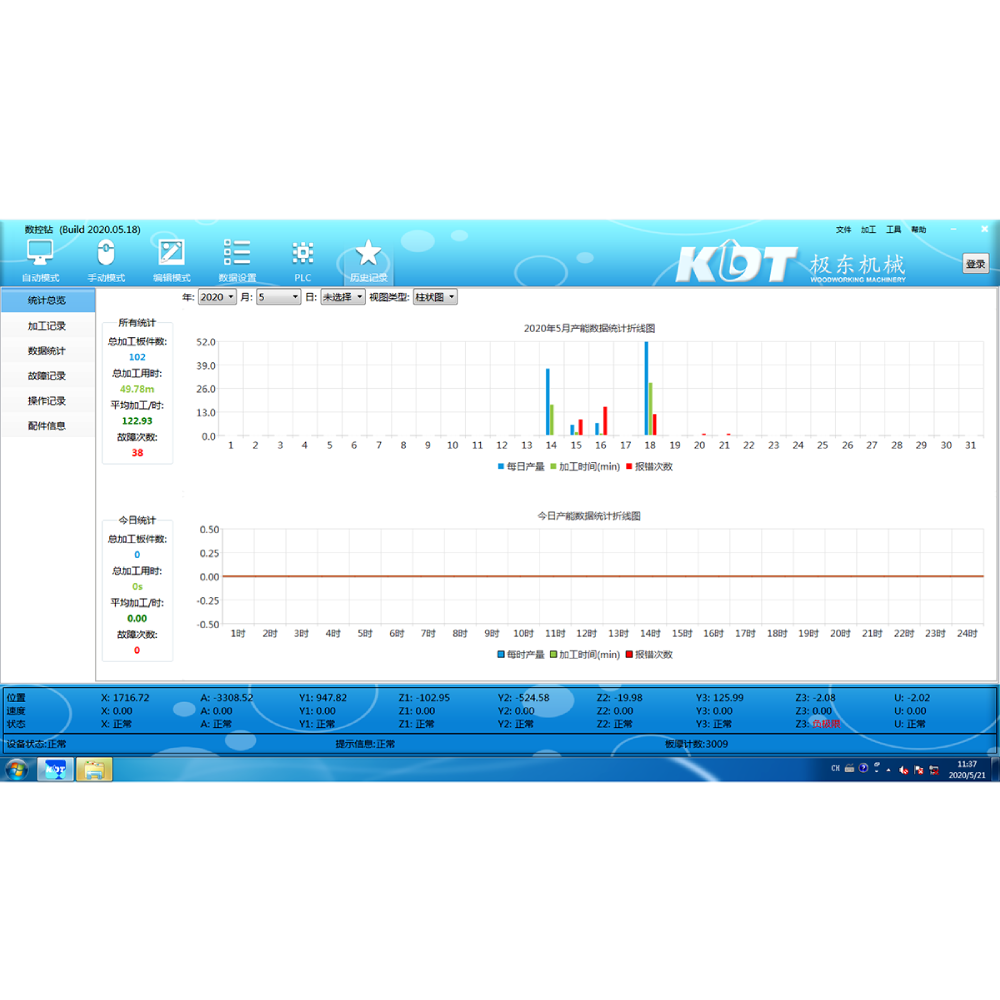

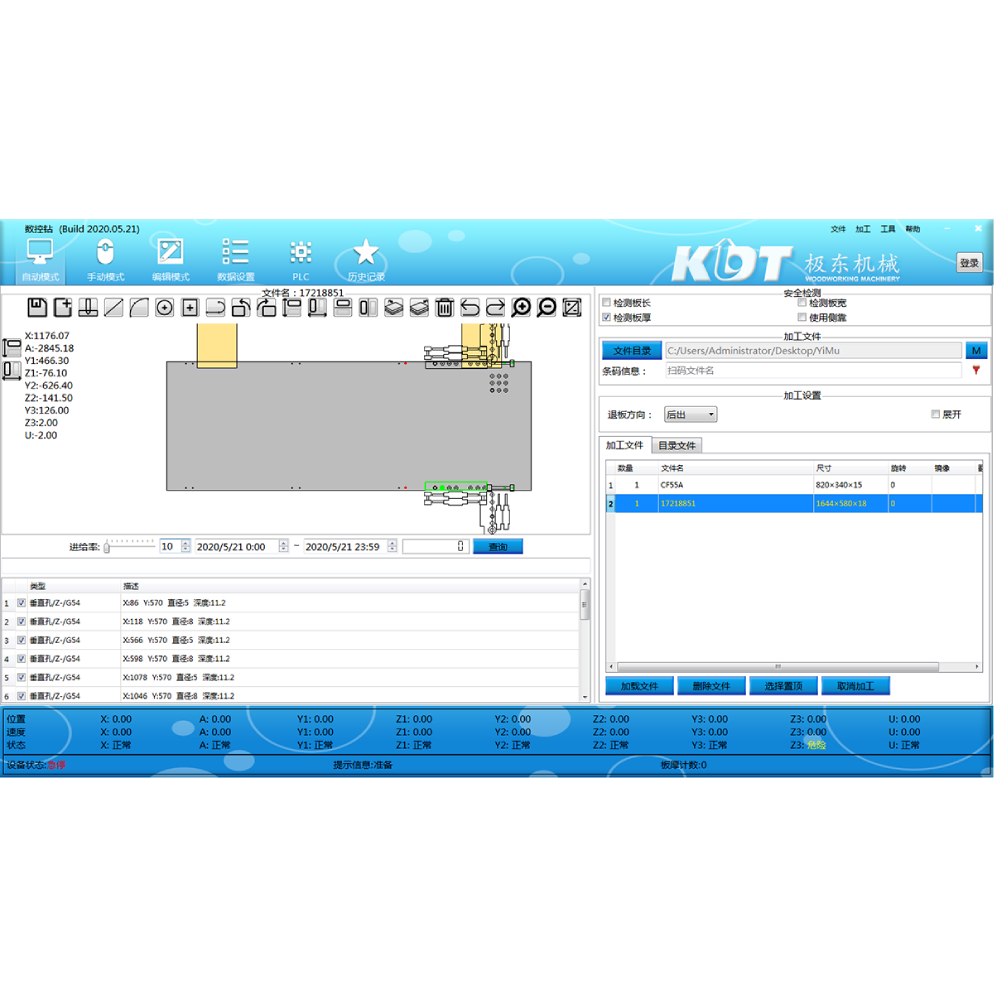

The machine is controlled by the user-friendly KDT DrillTop software on a DELL mobile control unit with a Windows environment. It is possible to connect the machine with programs such as MegaTISCHLER, IMOS, Corpus 3D, LestrojBox, Alphacam and Solidworks.

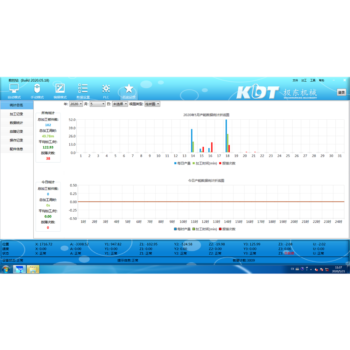

The KDT DrilTop program is easy to use, is graphically supported (CAD) and parametric. Processing simulation and work statistics are already included in the standard package.

Using the machine is easy, as it does not require mechanical settings.

The machine is safe for the user and is manufactured according to EU standards. Adapted safety fence and safety photocells.

Technical characteristics and equipment of the machine KDT KN-612 KSA (KHSA)

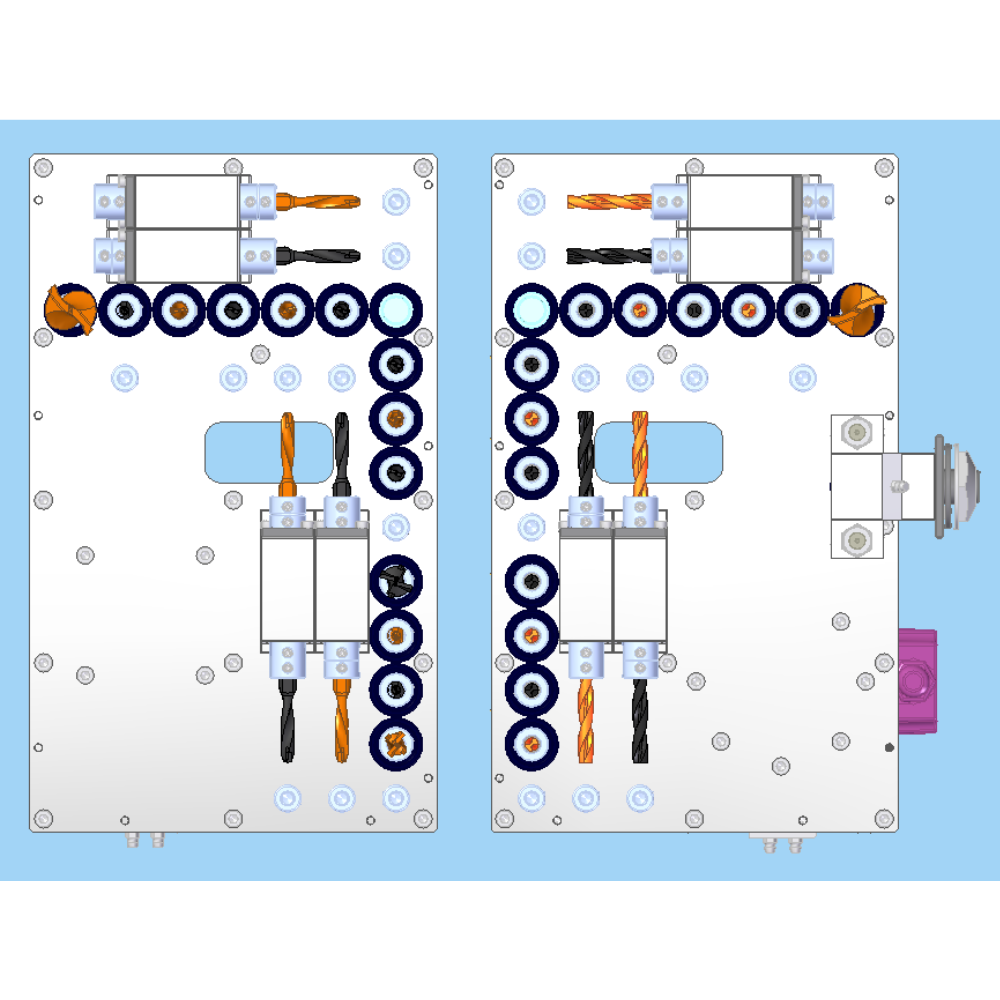

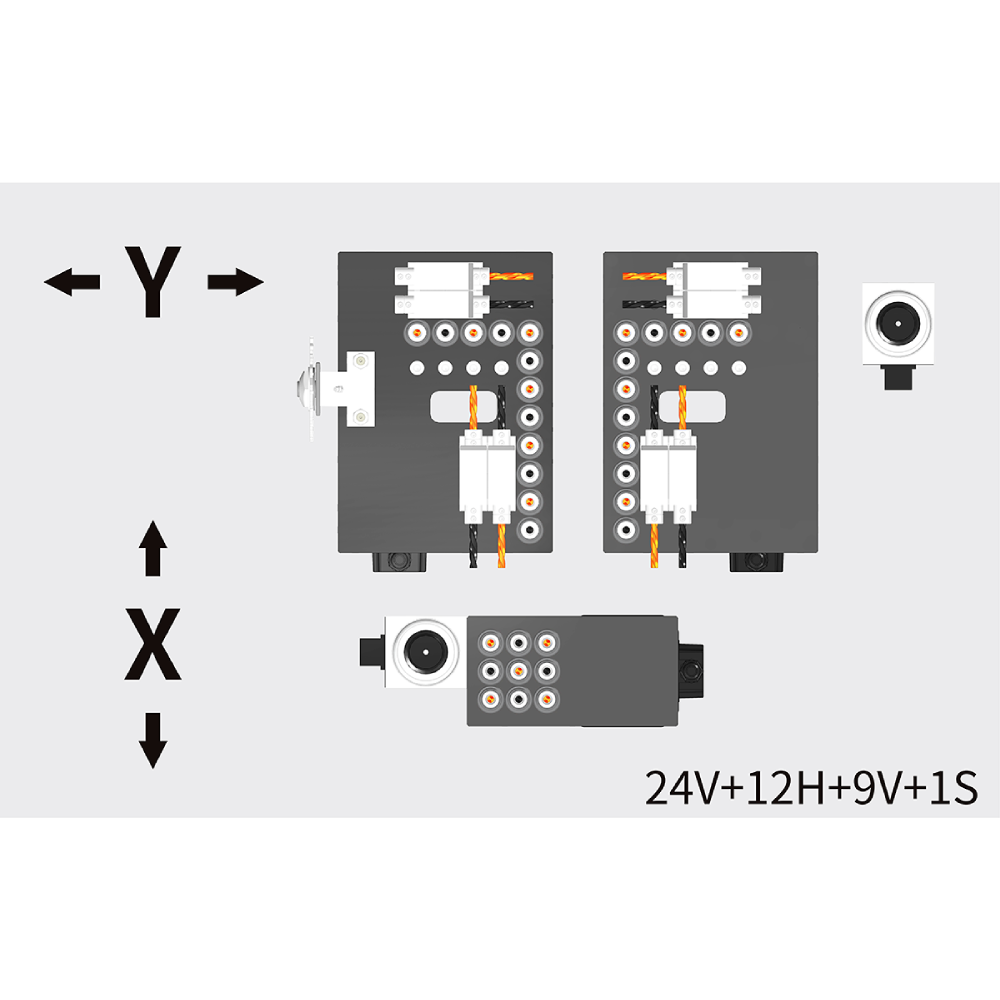

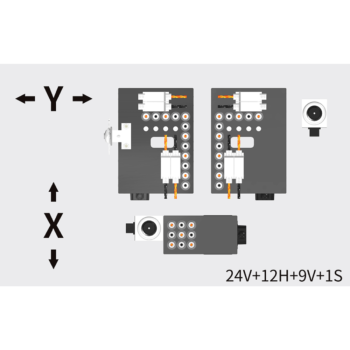

- Three independent Protean drilling units with 18 + 18 drills (24 vertical + 12 horizontal drills) and 9 bottom drills - total 45 drills - processing all 6 sides,

- integrated grooving saw for the back of 120 mm in diameter,

- 2x milling unit - top, bottom, 5 kW and 3.5 kW with ER25 mounting,

- DELL computer (Windows 10) on mobile control unit,

- processing of all 6 sides of the workpiece,

- double tongs speed 140 m/min,

- roller track in front and back with the option of returning the workpiece,

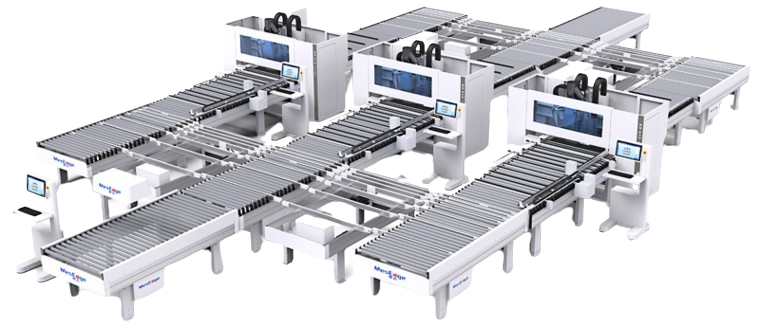

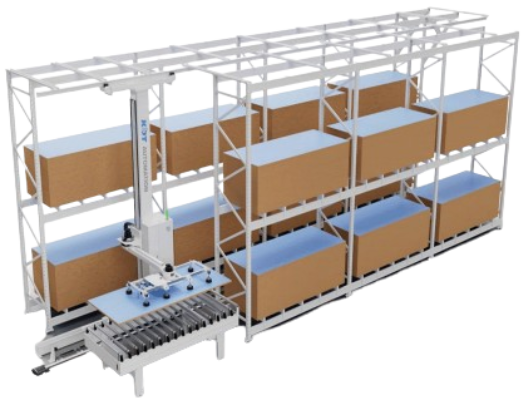

- possibility of upgrading the line with robotic manipulation of workpieces (loading, unloading),

- powerful KDT software via DELTA controller and DELL computer with Windows 10 environment,

- workpiece length: 250-2850 mm,

- workpiece width: 50-1200 mm,

- workpiece thickness: 9-60 mm,

- moving speed of the pliers: 140 m/min,

- Y axis speed: 75 m/min,

- overall dimensions: 7100 × 2855 × 2190 mm,

- total connected power: 30.12 kW,

- weight: 5000 kg.