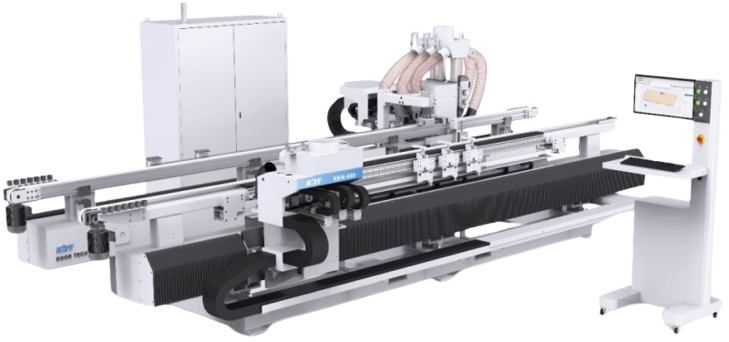

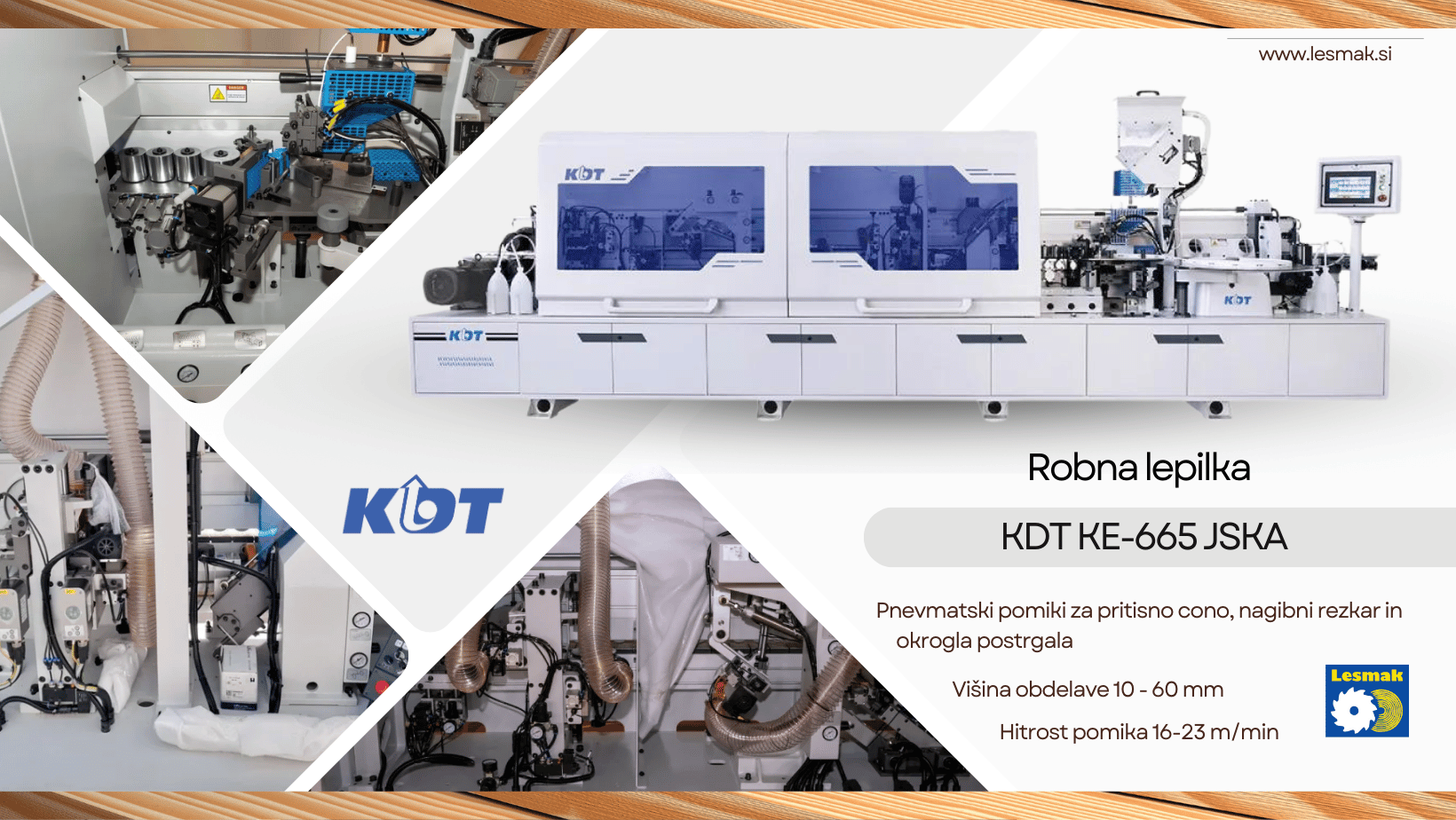

Edge Bander KDT KE-665 JSKA

The edge glue KDT KE-665 JSKA is a renewed model of the best-selling glue on the European market. It is an optimal relationship between exceptional reliability, size, productivity and affordable prices. In addition, maintenance is very easy and affordable.

Due to its smaller size (5.8m length), it is intended for both smaller companies and large companies, the machine is above average productive and reliable, mainly due to the strong base of the machine (construction) and industrial aggregates. This means that the machine can be used 24 hours a day, 7 days a week, while maintaining high quality standards.

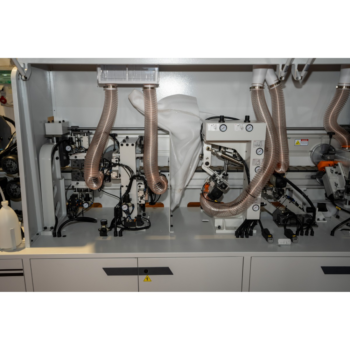

Work aggregates

DIA pre-milling machines, glue application, pressure zone of 5 rollers, planers, tilting mills, rondomat 2 motors, round and flat scrapers, brushes, liquid application.

Basic features of the machine

- Moving speed 16-23 m/min

- Pneumatic movements for the pressure zone, tilting cutter and round postgala

- Industrial PC

- Intuitive software for easy and fast work - 12 work programs

- Processing height 10 - 60 mm

- Dimensions 5850x940x1960 mm, weight 2500 kg.

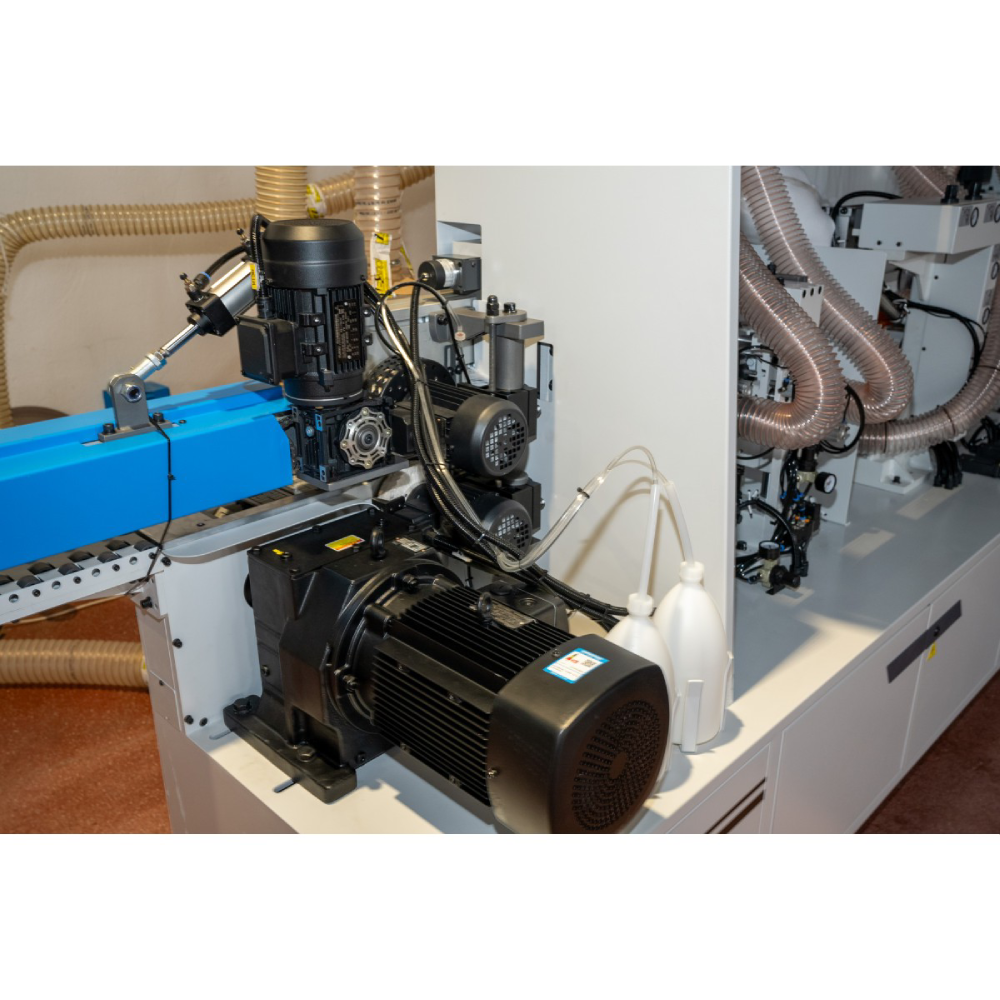

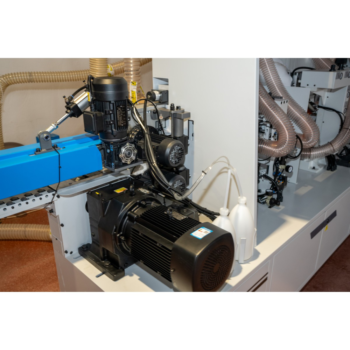

Advantages of industrial construction

The very robust monolithic and rigid construction of the machine, which is dimensioned with the most modern tools, 3D calculation and design programs, ensures high stability and enables the continuous operation of the machine 24 hours a day, 7 days a week, maintaining high quality standards. KDT uses the latest technology for the production of monolithic frameworks, with the selection of the best quality material, robotic welding, artificial aging to relieve tension in the structure and milling on the most modern CNC machines.

KDT guarantees you the most reliable operation through hours and hours, days and days of use, without constant adjustment of the machine.

Premium glue pot

The modern glue exchange kettle allows easy use of EVA and PUR glues. It enables easy automatic change of glue with the help of an additional chamber for drying, maintenance and preheating of the glue kettle.

The additional kettle (opt.) can be preheated without using the machine, which means that we do not lose valuable time when changing the type of glue. This means that we can use 2 different glues within 2 to 3 minutes, which is impressive.

Glue preheating allows constant addition of a minimum amount of glue to the main kettle. This ensures the freshest adhesive throughout use and consequently better quality joints.

Pneumatic movements of aggregates

With pneumatic and manual adjustment, we can achieve a more perfect appearance with different thicknesses of thin strips. Numerical indicators allow us to easily and reliably set up the machine.

Drive belt instead of wheels (option)

Most industrial shredders offer an optional top belt for moving workpieces through the machine. When the belt hugs the workpiece, it is less exposed to contact and the possibility of dust sticking to the surface of the workpiece. Highly recommended for use on very sensitive surfaces.

Efficient extraction

The machine already has suction connections installed as standard. They have a larger diameter, which ensures more efficient suction.

2 different liquid application units

For perfect final results, KDT edge adhesives are equipped with the application of a separating and cleaning agent.

A release agent prevents excess adhesive from sticking to the top and bottom surfaces and a cleaning agent that helps the brushes and scrapers to be more efficient.

Double rondomat for perfectly finished corners

Rondomat is equipped with two high-frequency motors and pneumatic position adjustment with two positions. It enables the processing of 4 different corner profiles, flat and rounded (softforming).

This rondomat enables processing of an optically perfect corner without manual correction.

Round and flat scrapers for a top finish

Industrial scrapers do their job better than most machines on the market. Stability during processing, large diameters of copying wheels, efficient suction, pneumatic pliers for removing chips from workpieces.