Categories

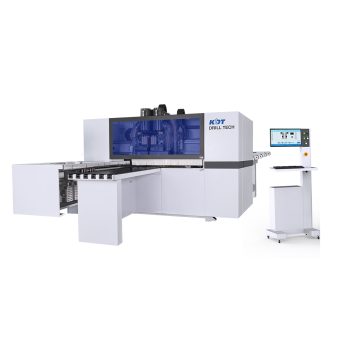

NC Drilling/Routing Machines

Automatic tool change | 1000 mm working width

The KDT KD-610 HZ is our most capable Drilling/Routing CNC machine.Powerful and very affordable.Configuration: 2 drilling units, 2 milling units, groove saw, automatic tool change 5 positions, 1000 mm working width!6 Side Machining -One drill head is mounted on the top, one on the bottom (20 + 9 drills). Possible processing of two workpieces at the same time.Extraordinary processing speed: 140/90/50 m/min.Groove saw 120 mm.Milling aggregate with automatic tool change 5 positions.Possibility of using ANGLE HEAD.The minimum dimension of the workpiece is only 70x35 mm.Powerful software equipment with many innovative solutions for fast and more efficient work.Barcode reader.Includes software for LestrojBOX furniture construction.

Edge Banders

Speed up to 18m/min

The KDT KE-706 Edge Bander is an upgraded version of the best-selling model on the European market, which combines an excellent balance between reliability, compactness, productivity and accessibility. Its maintenance is both simple and economical.Complete configuration with two different radios and servo drives. Speed up to 18 m/min!

Universal CNC Machines

Classic four-axis CNC machining center KDT KP series for every carpenter. Excellent features, quality components and an extremely affordable price that will convince many carpenters.

Edge Banders

Feed 16-23 m/min

KDT KE-665 JSKA Edge Bander is a renewed model of the best selling bander on the European market. Feed 16-23 m/min, industrial aggregates, complete equipment, pneumatic settings. It is an optimal relationship between exceptional reliability, size, productivity and affordable prices. In addition, maintenance is very easy and affordable.

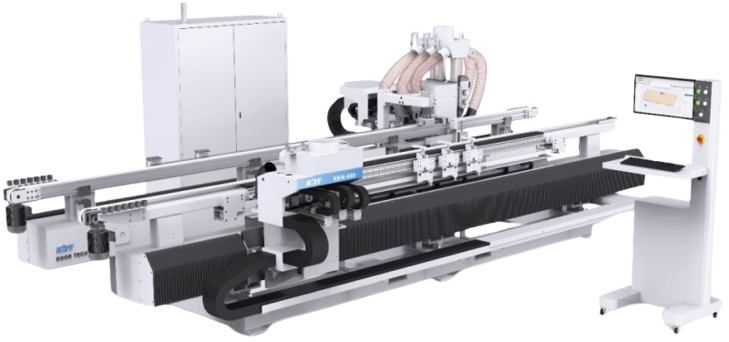

NC Drilling/Routing Machines

4 Axes | 6 Sided

2 machines in one! Speed and flexibility combined in one!Advanced extremely flexible technology for your production. Complete processing in one pass.The KD-612G represents the pinnacle of innovation and technical excellence, intended for the efficient processing of demanding products (elements for caravanning, massive flat products, ...)Designed to meet the needs of modern manufacturing, the KD-612G offers a wide range of machine usage options that increase productivityflexibility and ensure accuracy in every step.The machine is also very suitable for processing sensitive materials

Universal CNC Machines

Discover the premium 3-axis CNC machining center of the KDT KP series, designed with the modern carpenter in mind. With impressive technical features, premium components and an extremely competitive price, this machine is ready to satisfy the needs of even the most demanding carpenters.

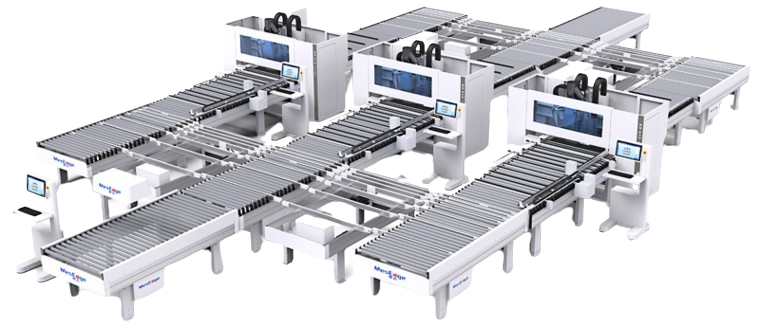

NC Drilling/Routing Machines

A highly productive machine with simultaneous drilling/milling of two workpieces at the same time,processing – drilling six sides of the workpiece,three independent drill heads (total of 49 drills), two routers, a grooving saw for the back,machine productivity: between 900 and 1200 workpieces/shift.

NC Drilling/Routing Machines

Superior Drilling/Routing CNC Machine with automatic scanning of workpieces in transit.Processing capacity up to 210 workpieces/hour orfrom 720 to 1680 workers per work shift (8 hours).

NC Drilling/Routing Machines

1000 mm working width

The KDT KD-610 H is the most basic KDT flow machining CNC machine.Powerful and very affordable.Configuration: 2 drilling units, 2 milling units, groove saw, 1000 mm working width!6 Side Machining -One drill head is mounted on the top, one on the bottom (20 + 9 drills). Possible processing of two workpieces at the same time.Extraordinary processing speed: 140/90/50 m/min.Groove saw 120 mm.5.5 kW milling unit with MK2 attachment.The minimum dimension of the workpiece is only 70x35 mm.Powerful software equipment with many innovative solutions for fast and more efficient work.Barcode reader.Includes software for LestrojBOX furniture construction.

CNC Nesting Machines

The CNC nesting machine KDT KN-3710D is an industrial CNC nesting machine designed to enable accurate and high-quality processing from 20 to 25 m/min.The CNC machining center KDT has a flat matrix work table, intended for so. i.nesting processing, which is becoming more and more relevant even for smaller carpenters who want to optimize and automate the work process of making furniture or cutting material.